Product Spotlight: GRAVITROL® Extrusion Control Systems

Leave a CommentGRAVITROL® Extrusion Control Systems: The Complete System

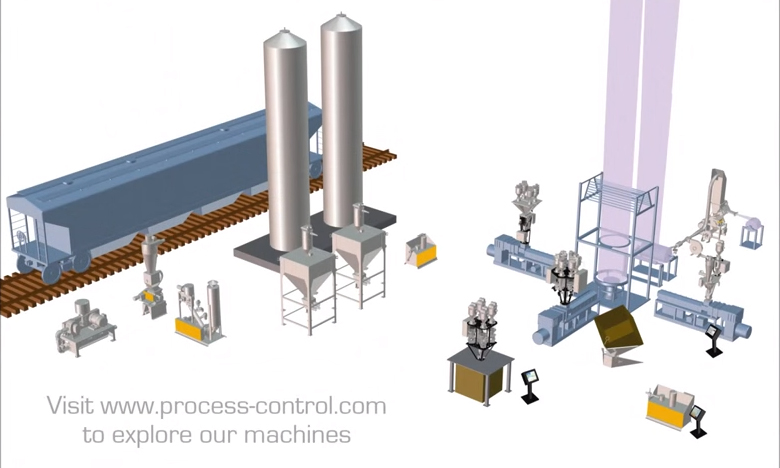

This week Process Control Corporation is pleased to spotlight its GRAVITROL® Extrusion Control Systems. Gravitrol® extrusion control offers the benefits of improved product quality, reduced material usage, quicker startups and product changeovers, reduced scrap, and improved product repeatability. At the same time, it reduces the operator’s workload by maintaining a constant output, regardless of screen pack or material variations.

The system uses Process Control’s proven Gravitrol® software to automate the control of the line and hold the extruder output to +/- 0.5% by weight. This tight control of output means that product can be made consistently within tolerance at the lowest possible cost, thereby saving thousands of dollars in resin.

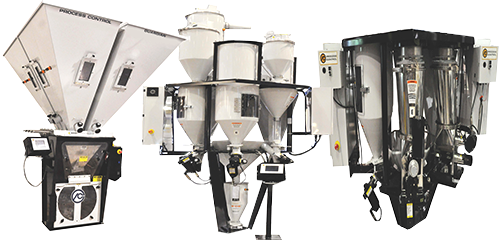

Process Control X Series blenders can be equipped with extrusion control software to allow the blender to control the extruder and line speed on monoextrusion lines for consistent output by weight. Guardian® batch blenders can also be equipped with weigh hopper and extruder and line speed I/O.

Control for X Series 2 Blenders

Process Control X Series 2 blenders monitor the extruder usage in order to follow the extruder rate and insure a consistent supply of material. In an extrusion control system, this extruder rate is used to adjust the screw speed by minute amounts to hold the overall throughput to the value entered in the blender operator station. Because the blender already has a powerful computer and equipment necessary to measure the extruder rate, adding extrusion control on a monoextrusion line with a Process Control X Series 2 blender is a very cost-effective addition. This feature can be easily retrofitted to existing installations with X Series 2 or B Series blenders.

X Series 2 blenders can also be easily integrated into coextrusion applications with extrusion control for controlling product layer ratios and total line throughput. On coextrusion applications the blender computer reports to a master EXB2 Series Operator Station, which also receives weight throughput reading from HG Series 2 Weigh Hoppers mounted on single-component extruders.

Check back next week for a brief introduction to the GRAVITROL® Extrusion Control Systems’ special features and products.

For this information and more on our GRAVITROL® Extrusion Control Systems, please click here to access our website, or send us an e-mail at sales@process-control.com.

Come see how easy to use, built to last, and impressively and carefully constructed Process Control’s products truly are.

Come see how easy to use, built to last, and impressively and carefully constructed Process Control’s products truly are.