PCC Recently Installed a 3 Layer Co Ex Line

Leave a CommentPCC Recently Installed a 3 Layer CoEx

PCC Recently Installed a 3 Layer Co-Ex Line featuring our new VacuBloc and EasyLink cost saving features.

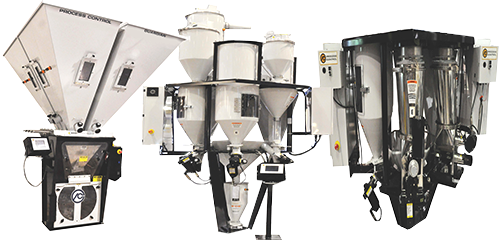

This new installation includes 3 of our state-of-the-art Guardian® Series 2 Gravimetric Batch Blenders providing precise batch-to-batch dispensing and consistent homogenous blending. Standard features include offthe-shelf controls, color touch-screen, quickly removable cartridge gates with V-gate metering, segmented material hoppers, integral drain chute, and a “No Dead Zone” mixing chamber. The Guardian® can be equipped with up to 12 ingredient hoppers, with each hopper capable of running 0-100% of the recipe with dispensing accuracy up to +/-0.02%. Guardian® Series 2 is comprised of six models, including 1.0kg, 2.5kg, 5kg, 12kg, 18kg and 25kg, with throughput rates exceeding 10,000PPH. Guardian® Series 2 blenders continue to set the standard for accuracy and blend homogeneity in each and every batch.

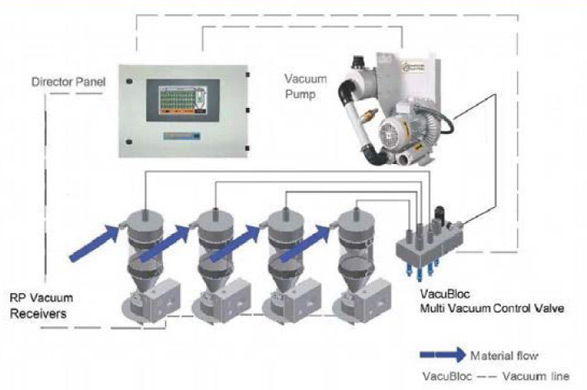

Our blenders are equipped with PCC VacuBloc manifolds that reduces the vacuum lines required to only one line per block. This saves in both materials and labor. The manifold holds all the sequencing valves that operate from the single vacuum line. The compressed air needed to operate the sequence valves also comes from our VacuBloc so you only need one compressed air line to the manifold. This gives you the ability to remote or blender mount the VacuBloc for easier maintenance and cuts down on installation time and costs.

Finally, the 3 layer line is equipped with PCC EasyLink

Easylink gives you the ability to run one Ethernet (24volt) cable from receiver to receiver. If it’s a co-ex line you still only run one Ethernet cable from each receiver blender to blender. The 24volt power would come from your Process Control blender. This dramatically cuts down on installation time and costs. The total savings for a 3-layer line conservatively totals $17k and even more savings for larger lines.