Author Archives: Richard Henderson

Process Control Laddawn & Gravitrol

Leave a CommentPCC Recently Installed a 3 Layer Co Ex Line

Leave a CommentPCC Recently Installed a 3 Layer CoEx

PCC Recently Installed a 3 Layer Co-Ex Line featuring our new VacuBloc and EasyLink cost saving features.

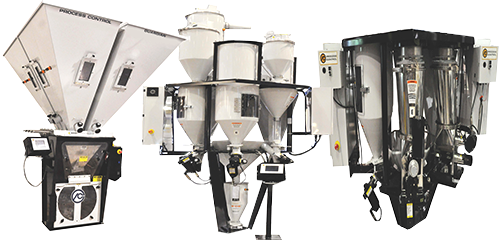

This new installation includes 3 of our state-of-the-art Guardian® Series 2 Gravimetric Batch Blenders providing precise batch-to-batch dispensing and consistent homogenous blending. Standard features include offthe-shelf controls, color touch-screen, quickly removable cartridge gates with V-gate metering, segmented material hoppers, integral drain chute, and a “No Dead Zone” mixing chamber. The Guardian® can be equipped with up to 12 ingredient hoppers, with each hopper capable of running 0-100% of the recipe with dispensing accuracy up to +/-0.02%. Guardian® Series 2 is comprised of six models, including 1.0kg, 2.5kg, 5kg, 12kg, 18kg and 25kg, with throughput rates exceeding 10,000PPH. Guardian® Series 2 blenders continue to set the standard for accuracy and blend homogeneity in each and every batch.

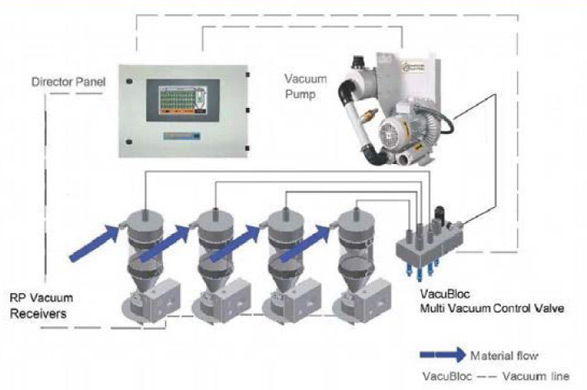

Our blenders are equipped with PCC VacuBloc manifolds that reduces the vacuum lines required to only one line per block. This saves in both materials and labor. The manifold holds all the sequencing valves that operate from the single vacuum line. The compressed air needed to operate the sequence valves also comes from our VacuBloc so you only need one compressed air line to the manifold. This gives you the ability to remote or blender mount the VacuBloc for easier maintenance and cuts down on installation time and costs.

Finally, the 3 layer line is equipped with PCC EasyLink

Easylink gives you the ability to run one Ethernet (24volt) cable from receiver to receiver. If it’s a co-ex line you still only run one Ethernet cable from each receiver blender to blender. The 24volt power would come from your Process Control blender. This dramatically cuts down on installation time and costs. The total savings for a 3-layer line conservatively totals $17k and even more savings for larger lines.

PCC Upgrades – Service

Leave a CommentPCC Special Project 2018

Leave a CommentPROCESS CONTROL

August 2018 PCC Special Project

P: 770.449.8810 F: 770.449.5445

6875 Mimms Drive, Atlanta, GA 30340 www.process-control.comProcess Control recently completed a custom job that includes a 25kg mixer only. The mixing chamber

was taken from the G2 Gravimetric Blender (as shown) and modified to include extra safety inter-

locks, a modified top plate for loading, and simplified controls. Once mixing stops, the cartridge

gate opens allowing material to gravity flow out the bottom of the

chamber. Blow- down with high pressure air streams also begins at stoppage and assists to quickly

empty all pellets from the mixing chamber.

This self-cleaning allows quick and easy change-over.

Process Control maintains a complete engineering staff including mechanical designers and

engineers, electrical, software and communication engineers.Please visit our website at www.process-control.com. For more information contact: Jim Collins at

(770) 449-8810 ext. 243 or jcollins@processcontrol.com.

Follow PCC for the Latest Company News:

Modified 25kg Mixing Chamber

25kg Gravimetric Guardian 2 Batch BlenderProcess Control Introduces New Rep Territory 1

Leave a CommentProcess Control is pleased to welcome Tom Richmond as our new territory 1 sales engineer. Tom graduated with honors from the University of North Georgia.

Tom is a veteran of the United States Marine Corps and was honorably discharged as a sergeant after six years of service. Tom has worked as a certified pipe welder and as a home inspector.

Tom resides in the Atlanta area with his wife and three children. Process Control is pleased to welcome Tom Richmond as the sales engineer for Georgia, Alabama, Tennessee, and Mississippi.