Process Control GmbH Celebrates 20 Years of Continuous Development

Located in Birstein, in the middle of Germany, Process Control GmbH was founded on April 1, 1994 as an independent subsidiary of Process Control Corporation headquartered in Atlanta, Georgia. At that time, the managing director Hans J. Sohn started with two employees with a business that was focused only on distribution from the USA.

Soon the local market needs were taken into account and a manufacturing facility was built for Europe in Birstein. The rented space in an office and production building reached capacity, so in 2003 the whole complex with 1600 m² total area was acquired. To this day, more than 1500 systems have been manufactured in this facility and were delivered to approximately 200 different customers in Europe, South Africa, the Middle East and China.

For our anniversary, we’re taking the time to look back on past accomplishments, but most of all we are looking forward under the motto of continuous development!

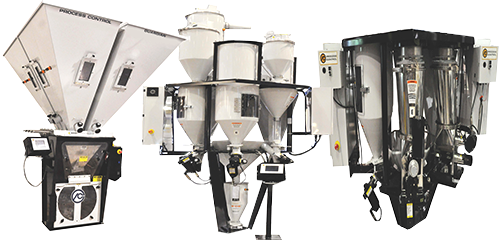

20 years of Process Control GmbH for us, our employees, customers and partners means trust, stability and especially growth. In the past, we have managed to react with newly developed products and offers to varying market requirements and have improved continuously. Know-how, expertise and motivated employees are necessary to achieve this goal. Especially in the area of developing special solutions for extrusion lines with smaller throughput rates, we were able to improve our continuous gravimetric blenders, the batch blenders and also the film grinders. On one hand, we have developed possibilities to meet lower throughput rates, and on the other hand, we can now fulfil the customer needs with a more compact design of our machines. In terms of energy saving, there were even more adjustments to achieve the greatest cost and CO2 savings.

We will continue to push innovations and offer the best possible service to our customers with our current team of 19 employees, with support from our representatives who are direct contacts in the different countries on-site.

In 2014, Process Control GmbH will be represented at several fairs for the plastics industry and we look forward to welcome you with our team in one of our booths.

Click here to visit the Process Control GmbH website.