Batch Blender with Auger Metering For Clumpy Material

Leave a Comment“TAKE 2”, GOT CLUMPY? That is, do you frequently have plastic pellets or regrind material that clumps together making it difficult to feed?

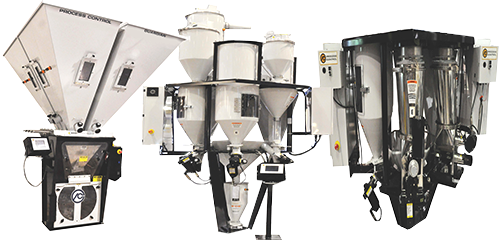

In February of last year we supplied several unique batch blenders that integrate the cost effective 12kg, 5 component Guardian Series 2 Batch Blender with auger metering. That design incorporated a remote mezzanine mounted material multi-hopper, due to customer height restrictions.

The latest version incorporates cylindrical material hoppers mounted on the blender base along with auger feeders for each component. As before, the blender base includes a weigh hopper and mixing chamber. AC motors equipped with variable frequency (VFD) drives allow frequent motor starting and stopping without overheating. As usual a powerful, off the shelf, color touch screen control provides user a friendly blender interface.

For more information on our unique engineering solutions, send us an email at sales@process-control.com.