Completing the ASR Part Two: The IN Series Trim Removal Inducer

1 CommentThe recovery of scrap generated during the production of blown film, cast film, tape and extrusion coating processes is a key element in reducing manufacturing costs. The Automatic Scrap Recycling system – or ASR®, for short – can recycle trim scrap and off-spec roll scrap in-line and turn your scrap back into profit without the expense of repelletizing.

A complete ASR system consists of several components, and for the next three weeks Process Control is pleased to detail this patented Automatic Scrap Recycling system. The three components covered will include the following: The RMX Series Refeed Machine, the IN Series Trim Removal Inducer, and the GF Series Film Scrap Grinder.

This week, PCC will be featuring the IN Series Trim Removal Inducer.

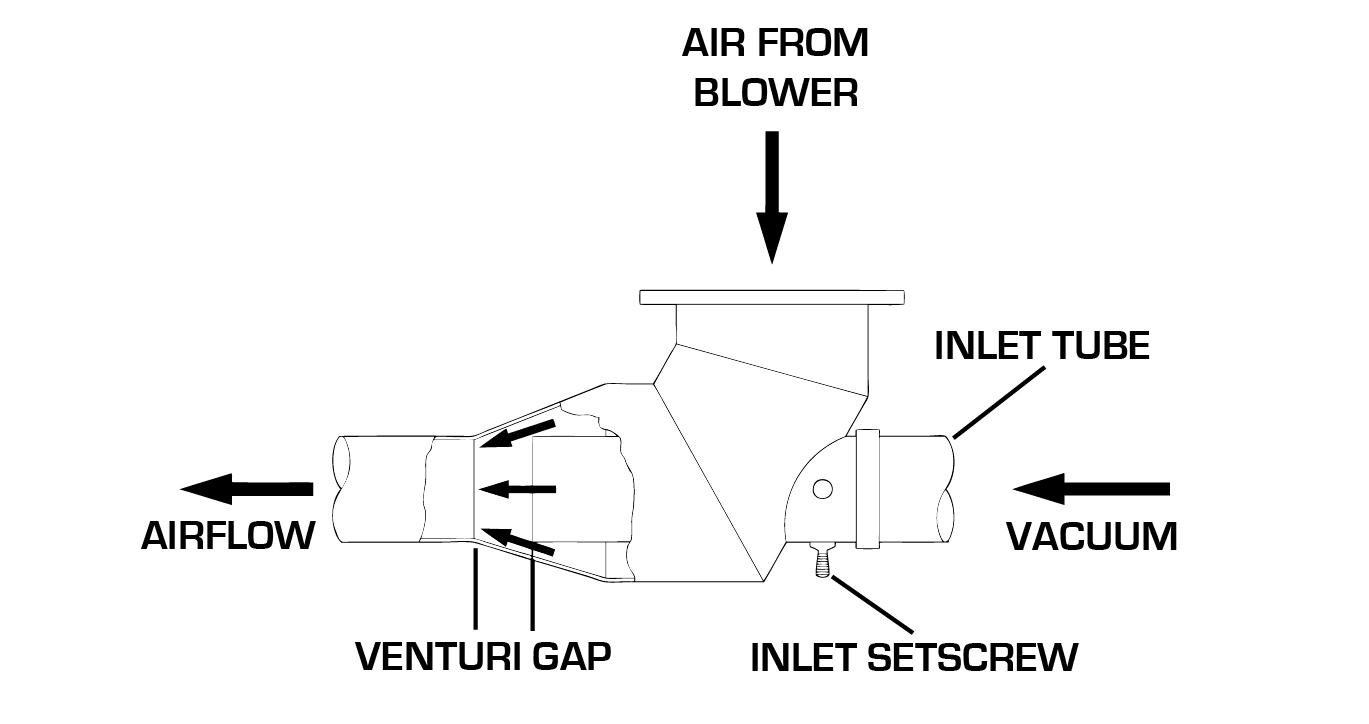

Process Control’s IN Series Inducers are designed to pick up and convey edge and/or bleed trims generated in the production of plastic film or other thin-gauge products such as foam, tape, paper or foil. These continuous trims are picked up by suction, conveyed into the inducer’s venturi section and blown to a destination such as a Process Control film grinder or a waste container.

Process Control inducer manifolds are designed to insure that the air velocity at the pickup point is maintained so that the trims do not wrap around the cutters. The IN Series inducers feature an adjustable venturi to allow you to tune the inducer for peak performance with your installation. IN Series inducers have a higher induced air to primary air ratio than conventional trim removal systems, providing excellent pickup and conveying performance.

IN Series inducers are designed to adapt easily to the installation requirements of your extrusion lines. The unit is shipped with its fan in a top-horizontal arrangement, but can be easily rotated in 90° increments to provide the required fan/venturi orientation. The fan may also be mounted remotely from the venturi using additional tubing.

Process Control’s patented venturi design uses the same principle used to create lift with an aircraft wing. The venturi design is far more efficient than the more commonly used cyclonic design, resulting in more suction and far greater air flow per fan CFM. This efficiency reduces the required horsepower, which results in lower energy costs, reduced noise and easier separation of the trim from the conveying air at the grinder.

Click here for more information on the IN Series Trim Removal Inducer.

For more information on the ASR® Automatic Scrap Recycling System and Process Control’s other products and upgrades , please visit our website or contact us directly at sales@process-control.com.