PCC Offers Total Integration Services

Leave a Comment

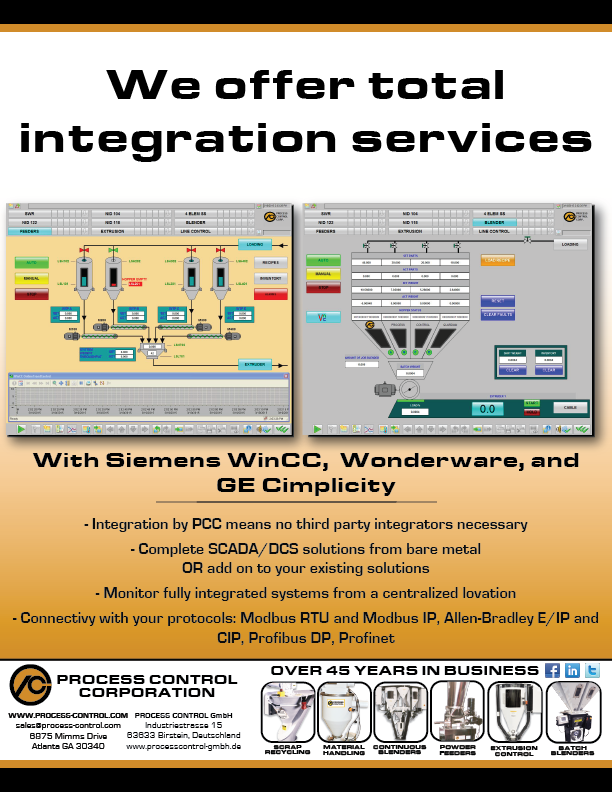

Process Control is pleased to announce that it offers total integrated services, allowing for a number of great new advantages:

- You can control and monitor all your PCC equipment on site from a centralized location, integrated with other systems from a single point of control.

- You can collect data and trending information from a single location.

- A more convenient location allows for SCADA and DCS screens with a better view of the process per screen.

- These SCADA and DCS solutions are complete from bare metal, or you can add them on to your existing solutions.

- These systems offer connectivity with your protocols: Modbus RTU and Modbus IP, Allen-Bradley E/IP and CIP, Profibus DP, Profinet

- The integration can be done with your systems: Siemens WinCC, Wonderware, and GE Cimplicity

New integration by PCC ensures familiarity with the equipment and the process. Now there is no need to rely on third party integrators who may not be as familiar with our product. You’re getting the most knowledgeable, most efficient support available.

To find out more about our integration services, contact Process Control at sales@process-control.com or learn more about the complete systems Process Control has to offer.