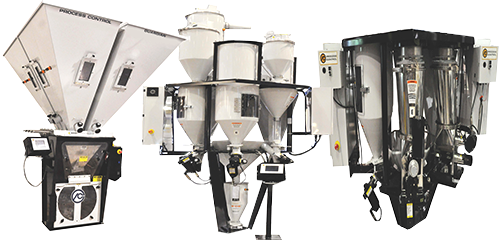

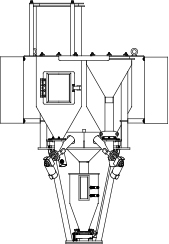

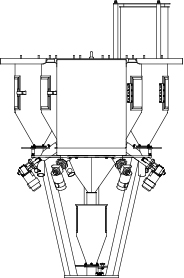

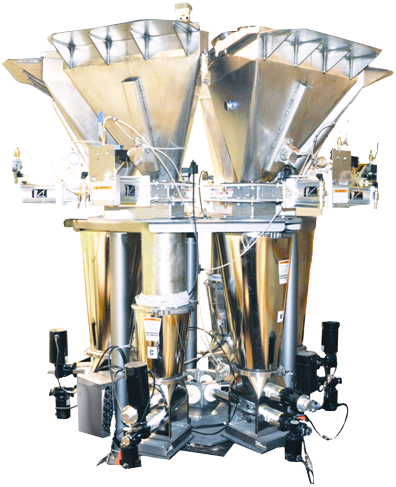

Product Spotlight: HG Series 2 Weigh Hopper

Leave a CommentToday’s product spotlight focuses on the HG Series 2 Weigh Hopper for extrusion control.

The HG Series 2 incorporates engineering and design breakthroughs to help achieve the optimal result in extrusion: a uniform product within tolerance at the lowest possible manufacturing cost. The touch screen interface will be able to communicate with a new supervisory system to be announced later this fall.

Click here to view the spec sheet for the HG2.

Please email us at sales@process-control.com for more information on this product.

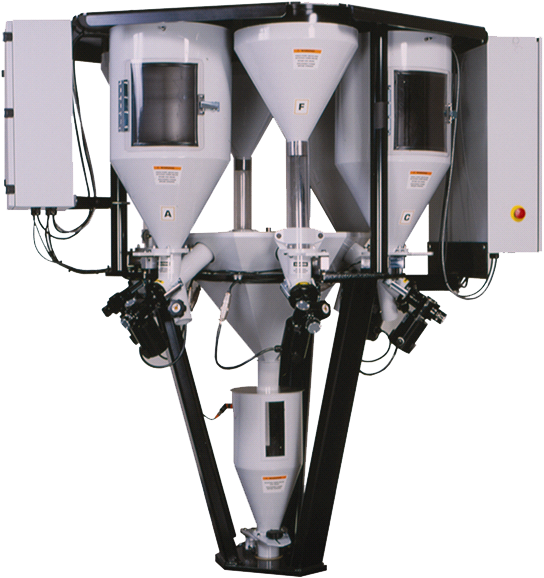

Standard Features:

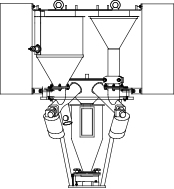

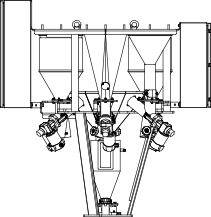

- Integral loader support platform

- Clear polycarbonate inspection/cleanout door (2.3 cu.ft. models and larger)

- Inspection sightglass (on 0.3 cu.ft. models and larger)

- Butterfly drain valve (on 2.3 cu.ft. models and larger)

- High-resolution PCC based weighing system

- Integrates with a complete Gravitrol extrusion control system for precise, consistent throughput control

- Mild steel construction

- Color touch screen operator interface

Options:

- Integral blender support for 2.5kg & 5kg Guardian Series 2

- High temperature design

- Stainless steel construction

- Special electricals

- Positive shut-off knife-gate or swing-gate valve for gravity loading material from above

- Integral extruder and line speed monitor/control