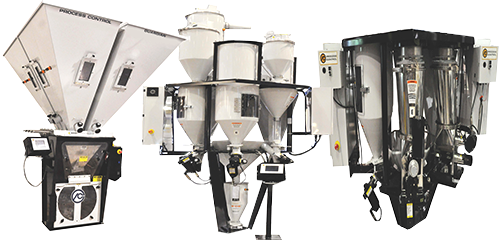

Previously we considered the importance of proper receiver sizing. In particular, we considered a standard receiver with flapper discharge automatically loading a continuous gravimetric blender utilizing a sequencing control.

Now we list some receiver options and features:

- Capacities range from 0.07 up to 5.0 cubic feet with body diameters of 12”, 16” or 20”.

- Steep wall (70 degree) cones and large discharge (up to 5”) for poor flowing materials

- RN Type with Pull-Out Pellet Screens

- Different screen mesh sizes available

- Oversized 12” x 12” Pull-Out Pellet screen available on 16” or larger diameter receivers

- RG Type with Nytex Filters for dusty materials

- RP Type with internal filter bags with automatic and continuous cleaning for dusty materials

- Material and Vacuum Line Sizes: 1.5” to 4.5” diameter in 0.5” increments.

- Carbon or Stainless steel construction

- Standard (up to 180 degrees F) or High Temperature (up to 350 degrees F) construction

- Air operated sequencing valve in lid of receiver

- Check valve for connection to common material supply

- Standard Discharge –Flapper of all metal construction means no wear parts (no seals required)

- Positive Control Discharge

- Knife Gate

- Swing Gate

- Control Voltages

- 110VAC

- 24VDC

- Connection Options (any combination of the following)

- Junction Box for landing wires

- Proximity Switches (load level)

- Connection cabling – DB9, IEC

Click here for more information on RN Series Vacuum Receivers and RP Series Vacuum Powder Receivers.