Product Spotlight: New RMX Series Refeed Machine Operator Panel

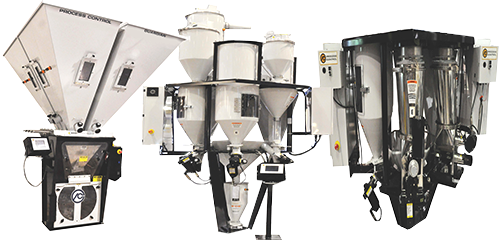

Leave a CommentProcess Control is pleased to present an all new RMX Series Refeed Machine Operator Panel available for ASR® Automatic Scrap Recycling. Hardware includes an HMI/PLC combo with Digital and Analog I/O, Modbus, & Ethernet. A variety of AC drive brands are available. The RMX Operator Panel can operate as a standalone system, or it can integrate with PCC (and most other) grinder and roll feed systems. It also comes with the ability to integrate with supervisory systems via Ethernet.

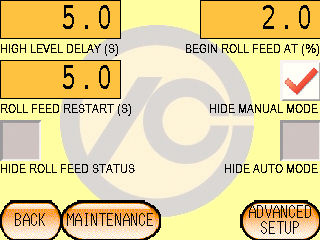

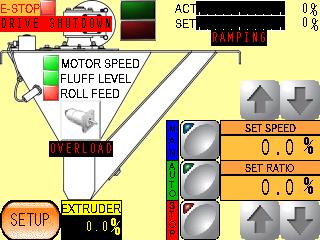

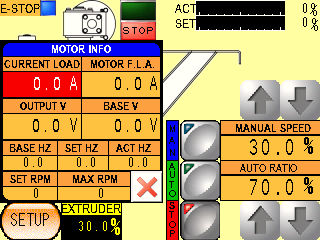

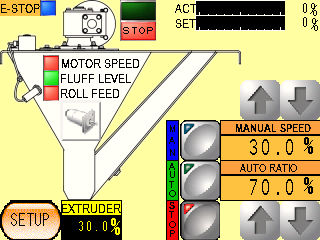

Operation modes for this panel include an auto, manual, and maintenance mode. Auto allows the user to set the speed ratio, and the PLC calculates the correct refeed speed based on extruder speed. Manual allows for direct speed entry, and maintenance provides forward and reverse job for cleanout and inspection. Advanced setup options for this panel include an ad adjustable rate/frequency curve for special materials and a simplified interface. This means you can hide the options you don’t need!

Most importantly, the RMX Series Refeed Machine Operator Panel provides a number of advantages. Smart HMI provides full control and configuration of drive system while competitors require in-panel adjustments. Monitor roll feeder and refeed status are read from a single screen, making the system easier and faster to read, plus system alarms are provided through a pop-up alert so it’s easy to find. Plus there is minimal drive setup because most of the parameters are set onscreen, and an easy switchover to various drive brands.

For more information on the ASR® Automatic Scrap Recycling System and Process Control’s other products and upgrades , please visit our website or contact us directly at sales@process-control.com.