Category Archive: Literature

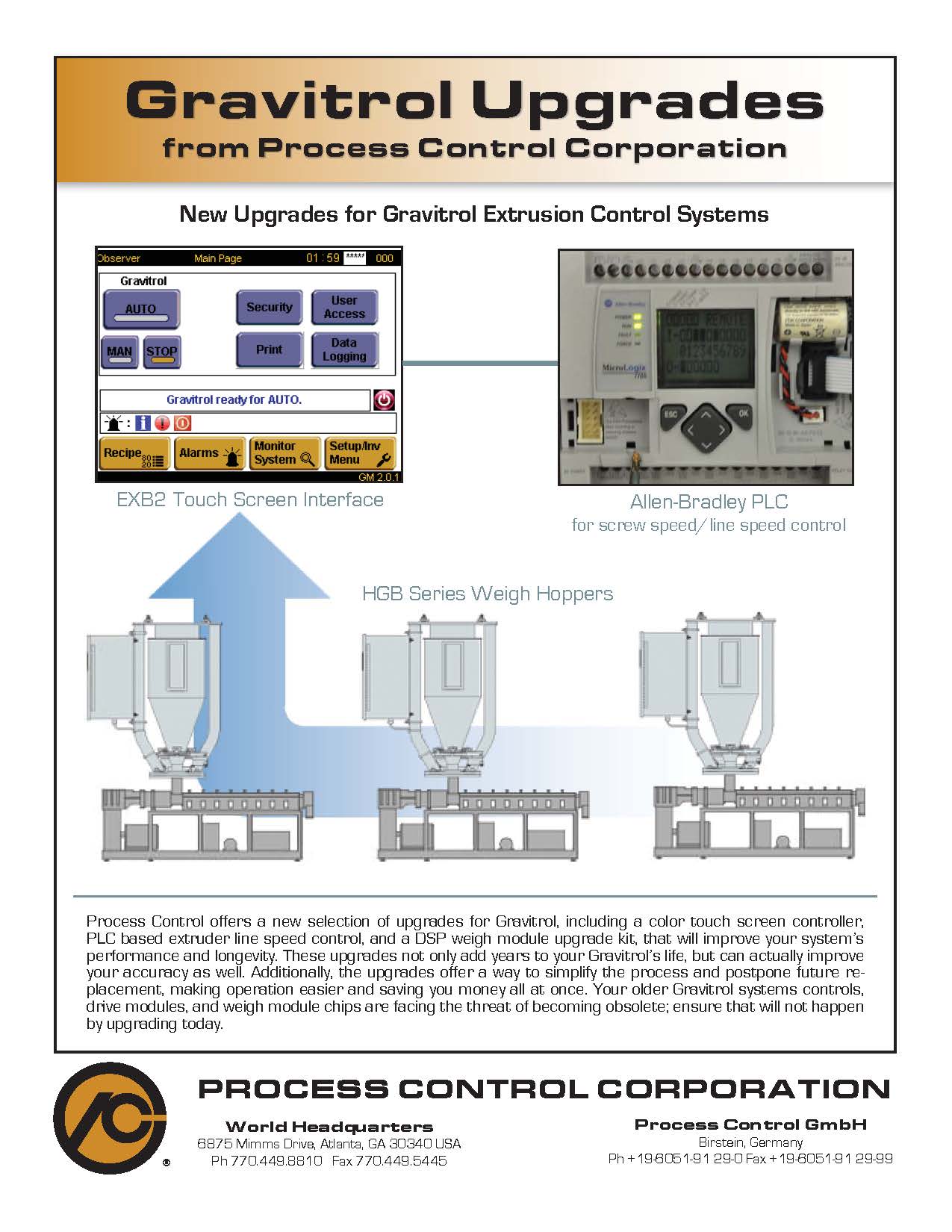

Process Control offers a new selection of upgrades for Gravitrol, including a color touch screen controller, PLC based extruder line speed control, and a DSP weigh module upgrade kit, that will improve your systems performance and longevity. These upgrades not only add years to your Gravitrol’s life, but can actually improve your accuracy as well. Additionally, the upgrades offer a way to simplify the process and postpone future replacement, making operation easier and saving you money all at once. Your older Gravitrol systems controls, drive modules, and weigh module chips are facing the threat of becoming obsolete; ensure that will not happen by upgrading today.

A new brochure is available detailing the features and pricing of our Gravitrol upgrades. Click here to download a copy.

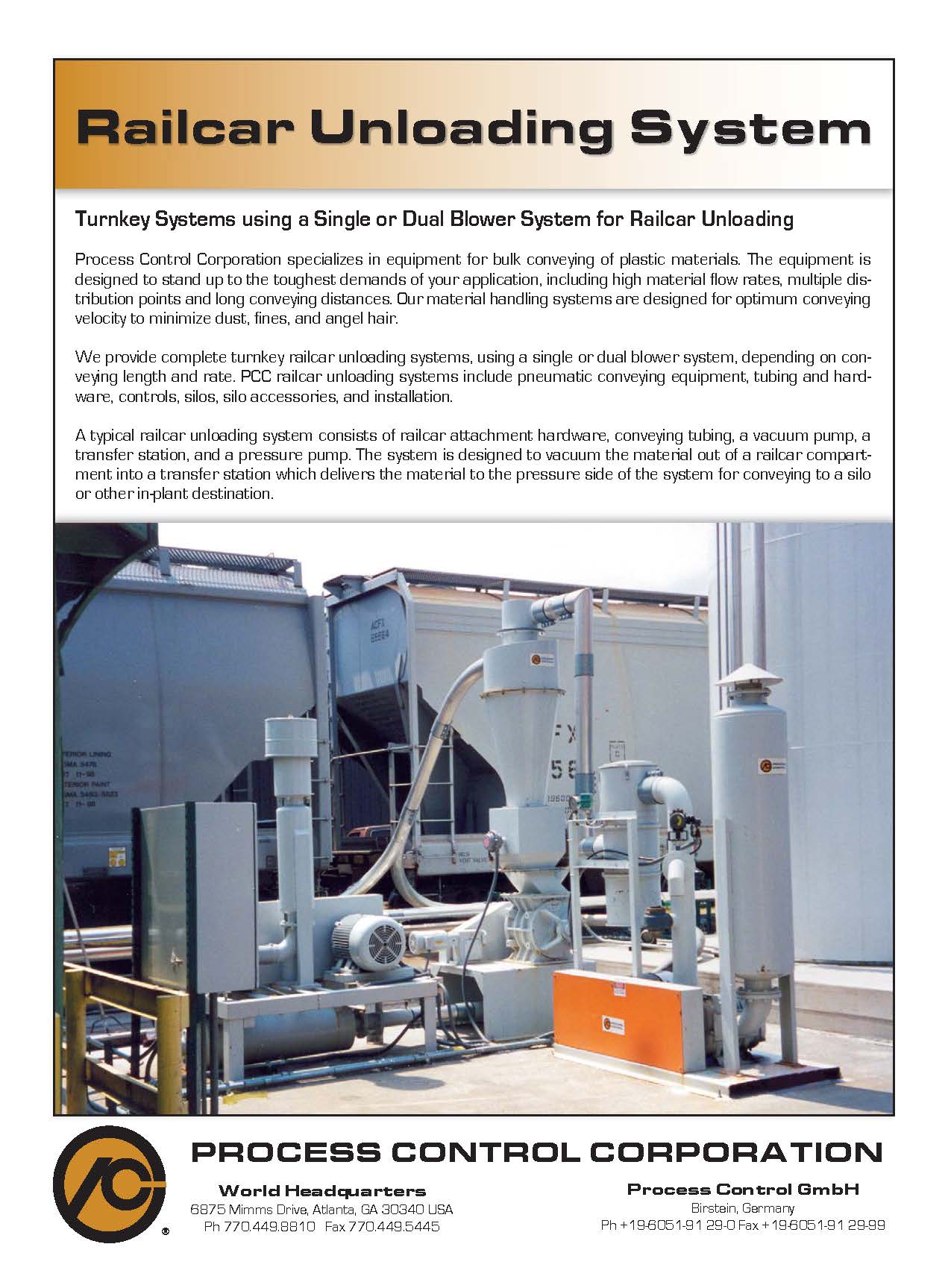

A new brochure is now available for PCC’s Railcar Unloading Systems. The brochure provides process flow diagrams to show single and dual blower systems, and it also gives an overview of the machines used for railcar unloading.

Process Control provides complete turnkey railcar unloading systems, using a single or dual blower system, depending on conveying length and rate. PCC railcar unloading systems include pneumatic conveying equipment, tubing and hardware, controls, silos, silo accessories, and installation.

Click here to download the Railcar Unloading brochure.

Click here to visit the Railcar Unloading section of our website for more in depth descriptions of the equipment.

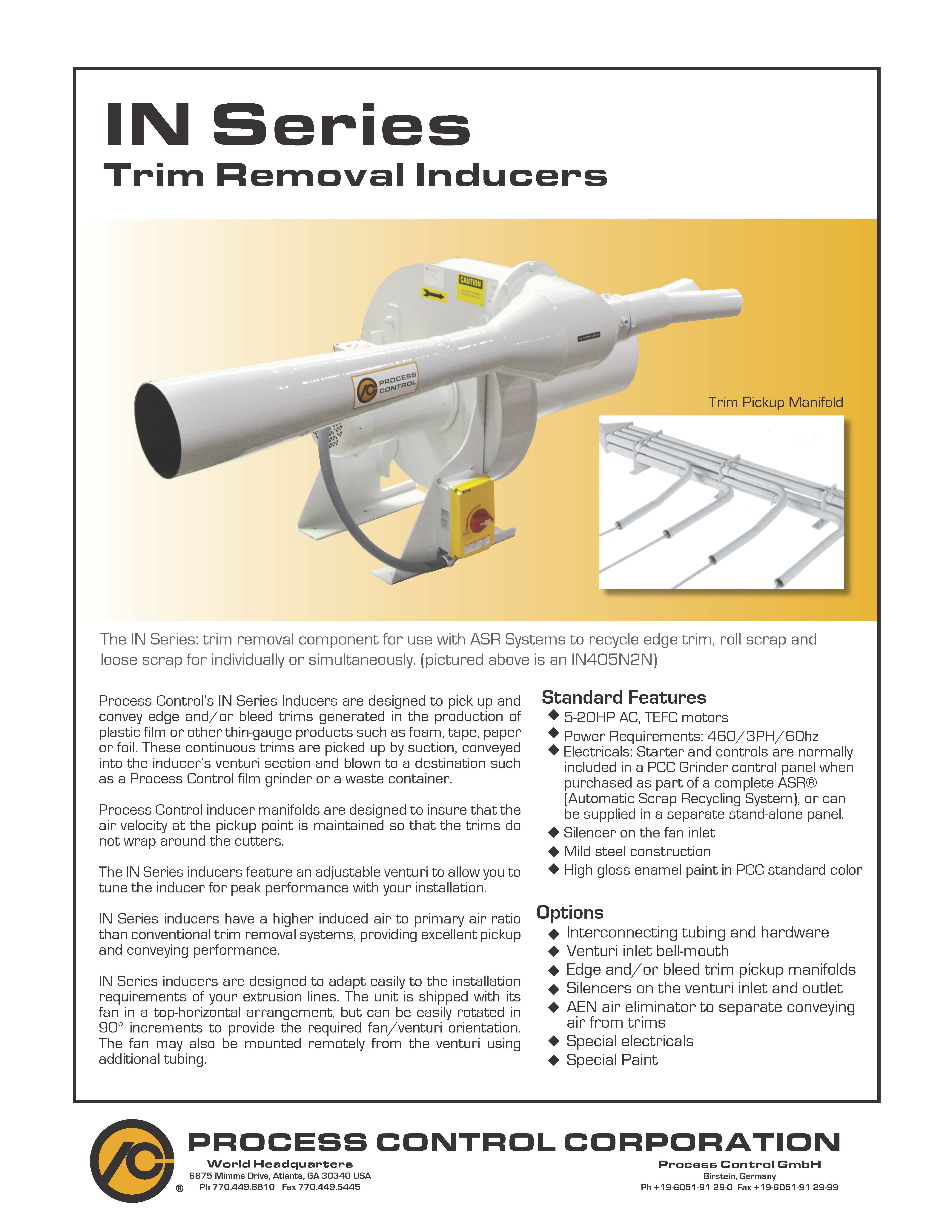

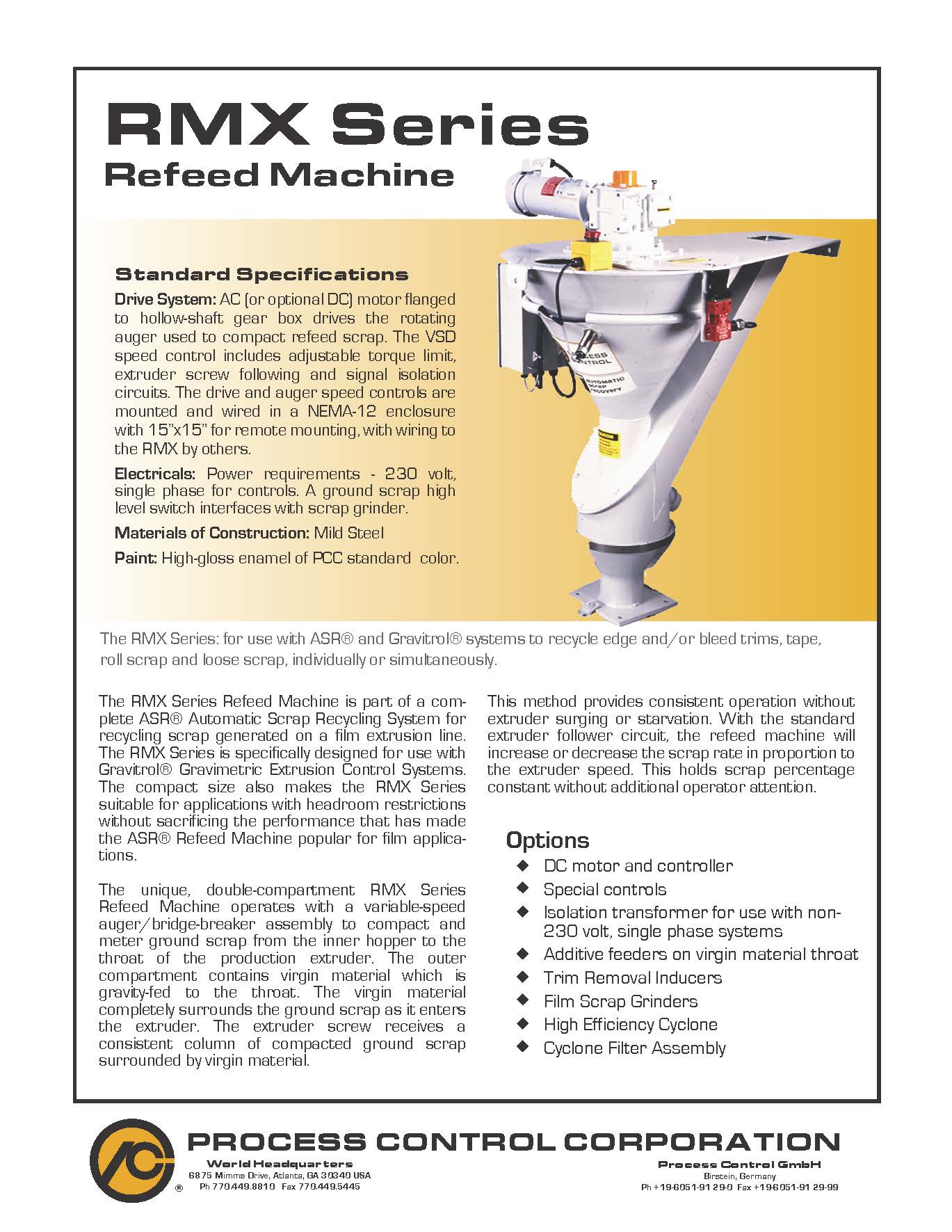

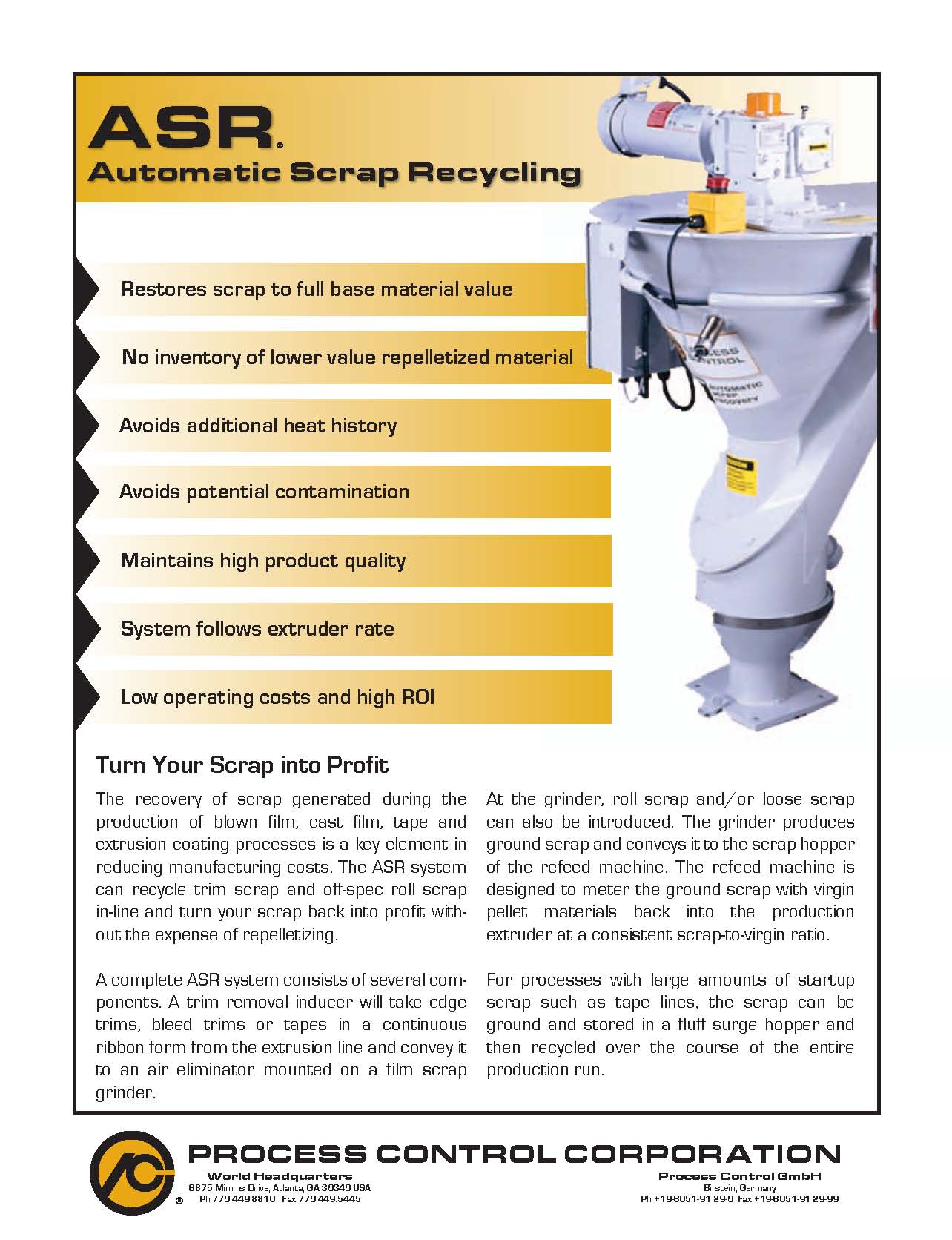

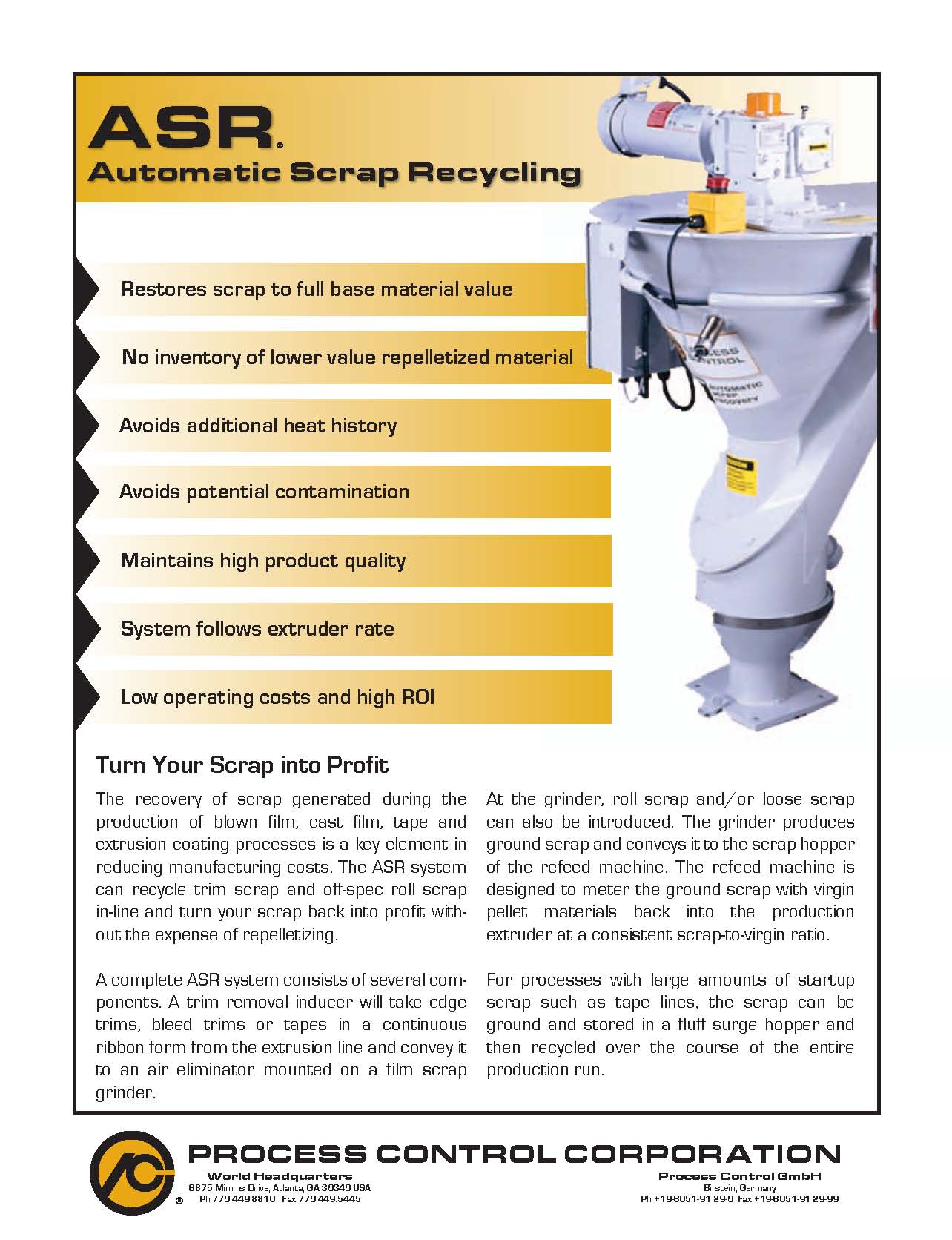

Process Control has released new, updated literature for each of the machines in our ASR® line of scrap recycling equipment. The cut sheets detail product specifications, features, options, and dimensions for each machine. To view the new literature, click the covers below!

If you have any questions or inquiries regarding any of the machines featured, feel free to email us at sales@process-control.com or contact your local sales representative directly with our Rep Locator.

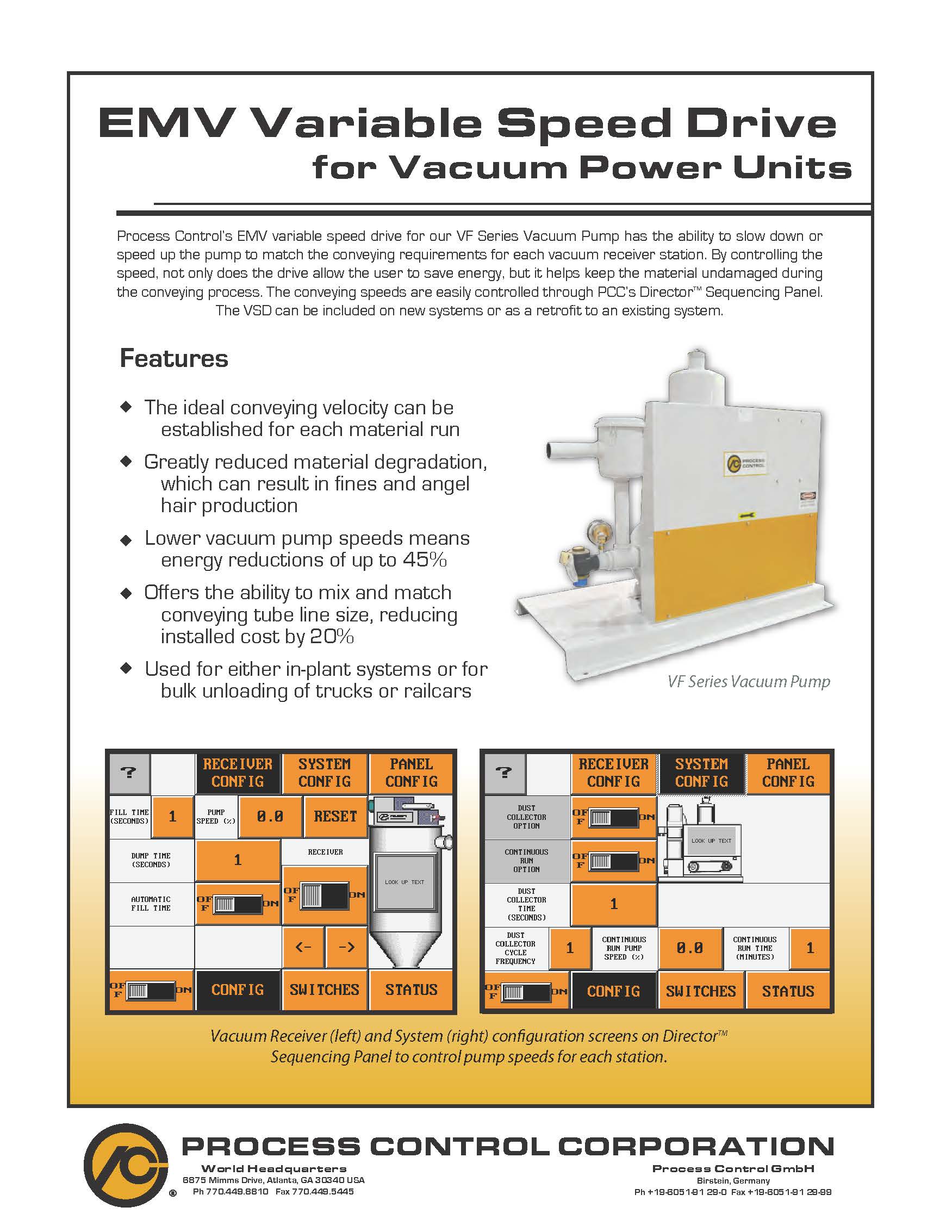

Process Control has released new literature for the EMV Variable Speed Drive. Click here to download!

The EMV variable speed drive for our VF Series Vacuum Pump has the ability to slow down or speed up the pump to match the conveying requirements for each vacuum receiver station. By controlling the speed, not only does the drive allow the user to save energy, but it helps keep the material undamaged during the conveying process.

Updated literature is now available for Process Control’s Gravitrol – Extrusion Control System. The new literature features the HG Series 2 Weigh Hopper with touchscreen controls and the new EXG Series supervisory operator station.

Gravitrol extrusion control offers the benefits of improved product quality, reduced material usage, quicker startups and product chagneovers, reduced scrap, and improved product repeatability. At the same time, it reduces the operator’s workload by maintaining a constant output, regardless of the screen pack or material variations.

Click here to download a copy of the new Gravitrol brochure.

PCC would like to announce the HG Series 2 – a weigh hopper (now with touch screen controls) designed for use as part of the Gravitrol Extrusion Control System. The HG Series 2 incorporates engineering and design breakthroughs to help achieve the optimal result in extrusion: a uniform product within tolerance at the lowest possible manufacturing cost. The new touch screen interface will be able to communicate with a new supervisory system to be announced later this fall.

PCC would like to announce the HG Series 2 – a weigh hopper (now with touch screen controls) designed for use as part of the Gravitrol Extrusion Control System. The HG Series 2 incorporates engineering and design breakthroughs to help achieve the optimal result in extrusion: a uniform product within tolerance at the lowest possible manufacturing cost. The new touch screen interface will be able to communicate with a new supervisory system to be announced later this fall.

Click here to view the spec sheet for the HG2.

Please email us at sales@process-control.com for more information on this product.

Standard Features:

- Integral loader support platform

- Clear polycarbonate inspection/cleanout door (2.3 cu.ft. models and larger)

- Inspection sightglass (on 0.3 cu.ft. models and larger)

- Butterfly drain valve (on 2.3 cu.ft. models and larger)

- High-resolution PCC based weighing system

- Integrates with a complete Gravitrol extrusion control system for precise, consistent throughput control

- Mild steel construction

- Color touch screen operator interface

Options:

- Integral blender support for 2.5kg & 5kg Guardian Series 2

- High temperature design

- Stainless steel construction

- Special electricals

- Positive shut-off knife-gate or swing-gate valve for gravity loading material from above

- Integral extruder and line speed monitor/control

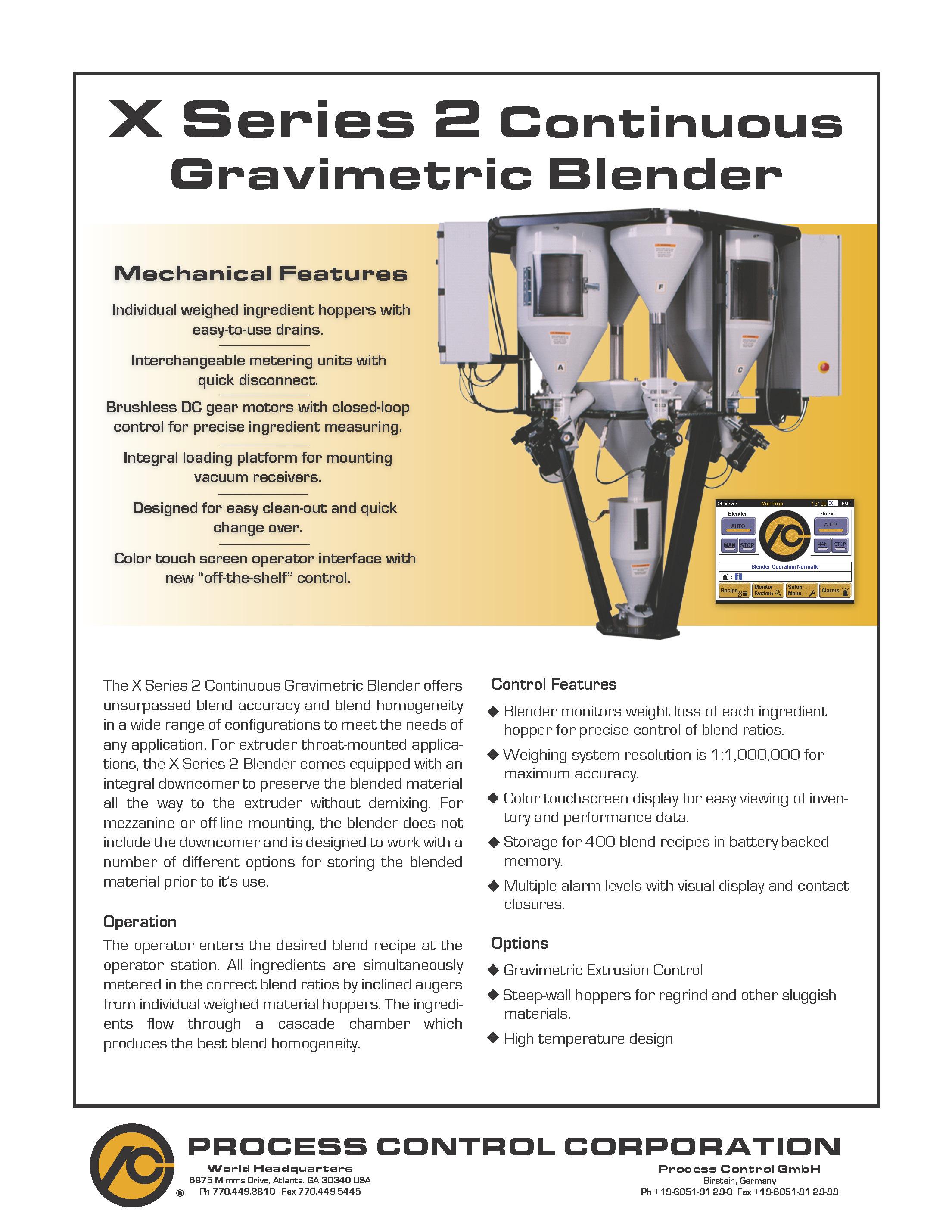

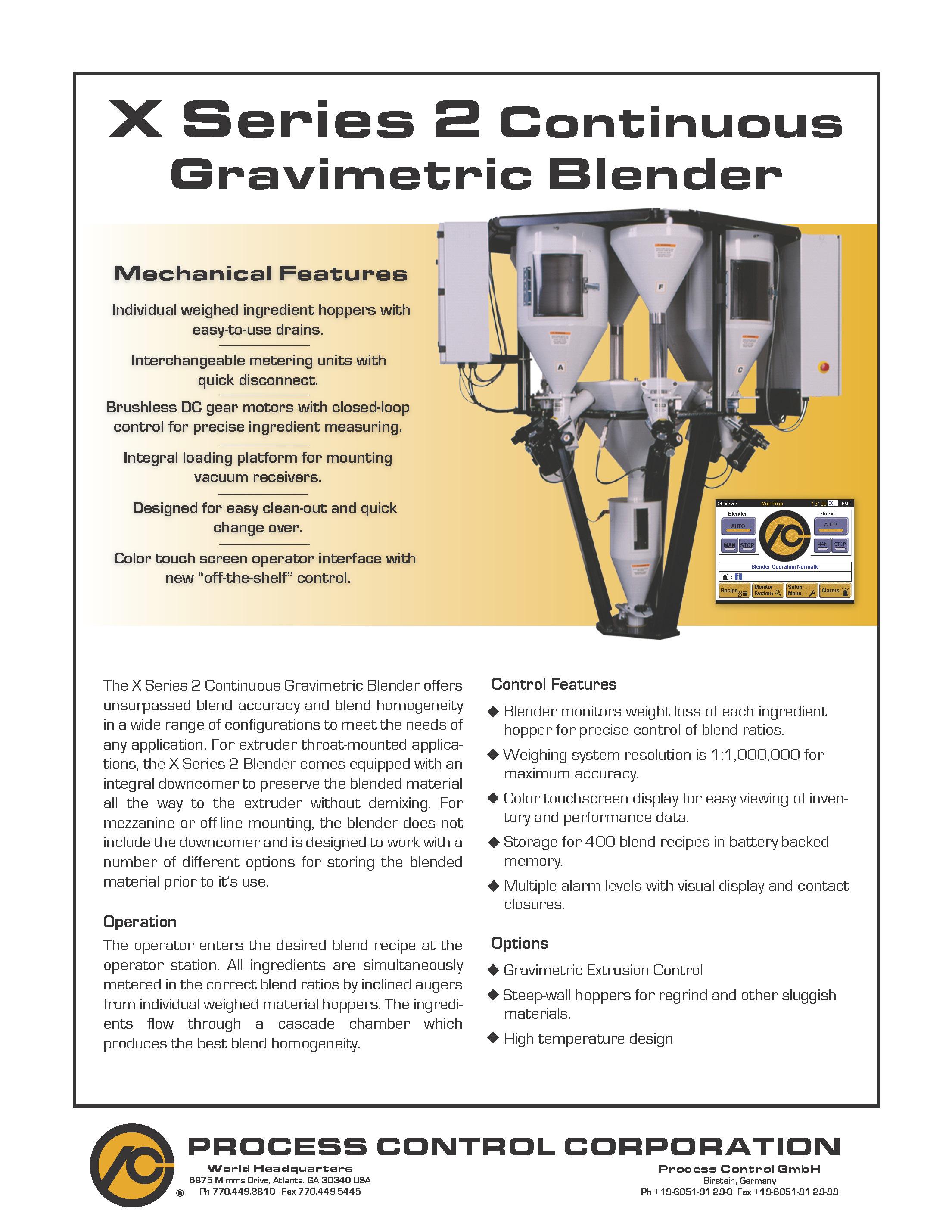

X2D6, small frame, 6-element complements the X2D4 four element frame, and completes the X2 Series along with the X2L4 and X2L6.

X2D6, small frame, 6-element complements the X2D4 four element frame, and completes the X2 Series along with the X2L4 and X2L6.

Features:

- Color touch screen operator interface with new “off-the-shelf” control

- Blender monitors weight loss of each ingredient hopper for precise control of blend ratios

- Weighing system resolution is 1:1,000,000 for maximum accuracy

- Storage for 400 blend recipes in battery-backed memory

- Multiple alarm levels with visual display and contact closures

- Color touchscreen display for easy viewing of inventory and performance data

- Brushless DC gear motors with closed-loop control for precise ingredient measuring

- Superior reliability and long lifespan

- Require only two power/gear ratio combinations to cover the required RPM range

- Available with integral or remote downcomer

- Individual weighed ingredient hoppers with easy-to-use drains

- Interchangable metering units with quick disconnect

- Integral loading platform for mounting vacuum receivers

- Designed for easy clean-out and quick changeover

Click here to download the X Series 2 Continuous Blender cut sheet and view X2D6 specs and dimensions.

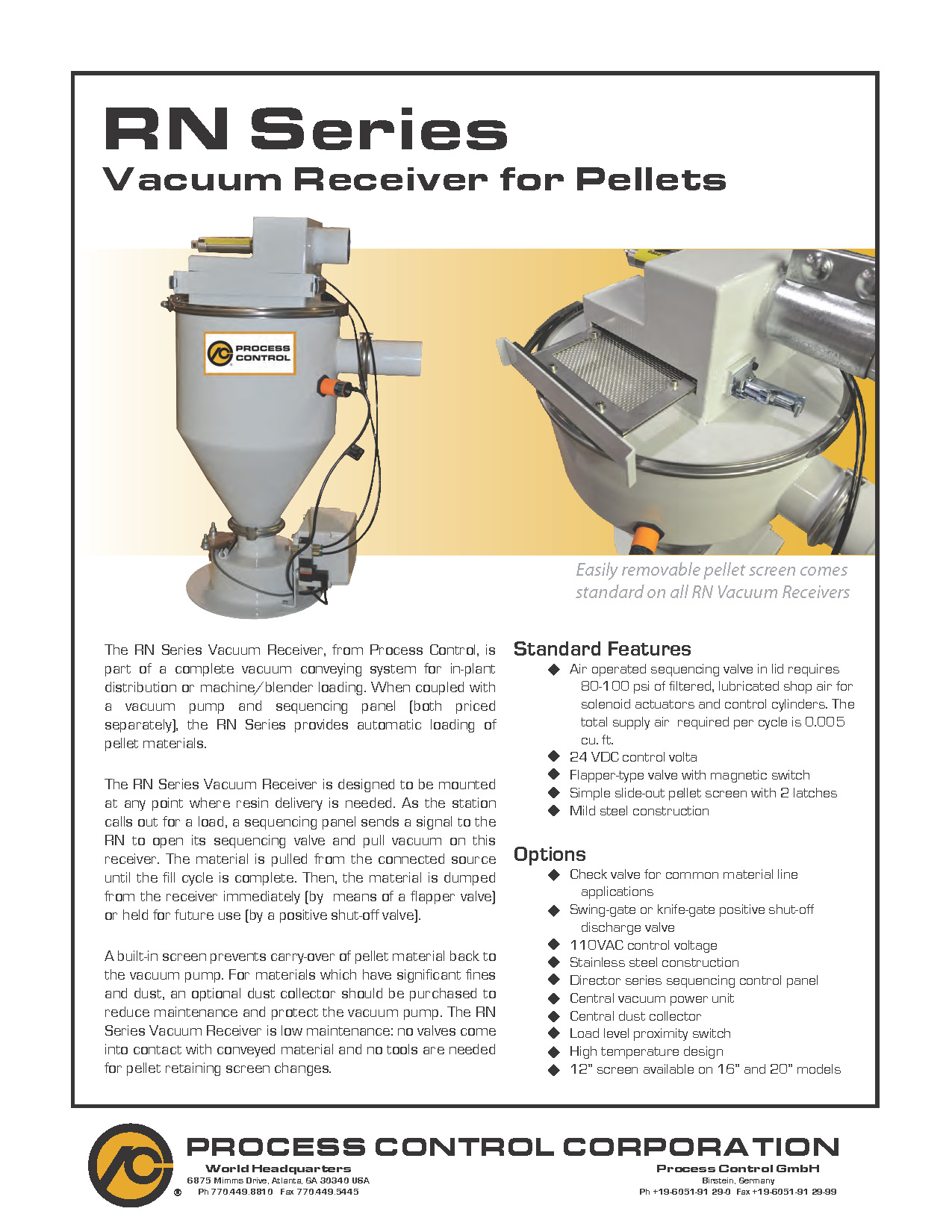

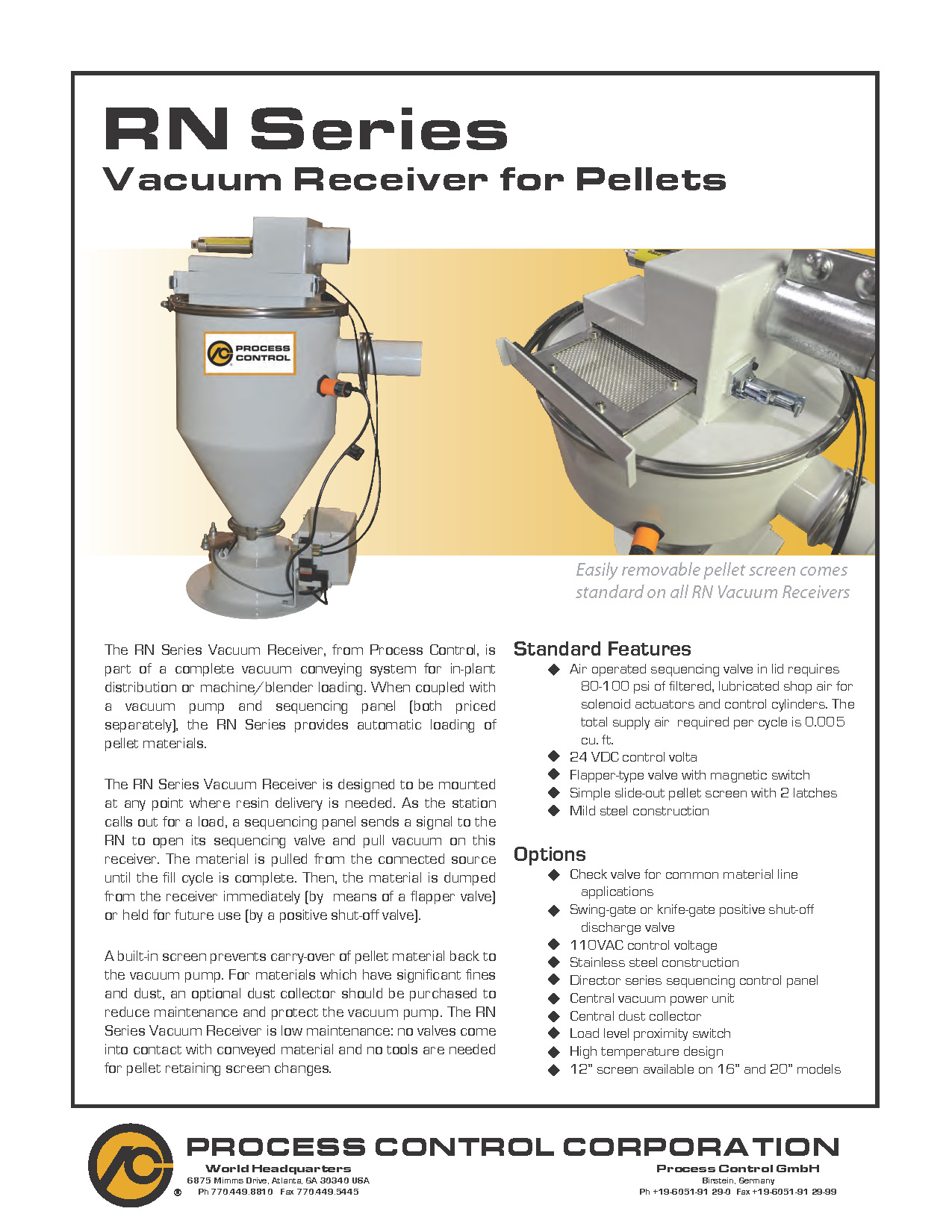

PCC has released and updated spec sheet for our RN Series Vacuum Pellet Receiver. The new literature details the features of the RN Series, including dimensional drawings for flapper, swing-gate, and knife-gate discharge valve models, standard features, optional features, and schematic diagrams for typical loading systems.

Click here to download the new spec sheet.

The RN Series Vacuum Receiver is part of a complete vacuum conveying system for in-plant distribution or machine/blender loading. When coupled with a vacuum pump and sequencing panel, the RN Series provides automatic loading of pellet materials.

PCC has released a new piece of literature on the next iteration of our X Series Continuous Gravimetric Blender. The X Series 2 comes standard with color touch screen controls as well as brushless DC motors and drives. To view specifications for this product, click here to view the X Series 2 cut sheet.

PCC has released a new piece of literature on the next iteration of our X Series Continuous Gravimetric Blender. The X Series 2 comes standard with color touch screen controls as well as brushless DC motors and drives. To view specifications for this product, click here to view the X Series 2 cut sheet.

PCC has created a new ASR® Automatic Scrap Recycling brochure to describe in detail a system that can turn your scrap material back into profit without the expense of repelletizing. The brochure discusses the benefits of the ASR® System as well as different applications in the plastics industry. The system is shown as a whole before being broken down into individual descriptions of the equipment, which have been specifically designed to create optimal results for scrap recovery. Click here to view the new brochure.

PCC has created a new ASR® Automatic Scrap Recycling brochure to describe in detail a system that can turn your scrap material back into profit without the expense of repelletizing. The brochure discusses the benefits of the ASR® System as well as different applications in the plastics industry. The system is shown as a whole before being broken down into individual descriptions of the equipment, which have been specifically designed to create optimal results for scrap recovery. Click here to view the new brochure.