Category Archive: Production

PCC recently shipped the largest order of ASR Automatic Scrap Recycling Equipment, in recent history, to Germany. The order includes multiple cutting chambers for GF Series grinders as well as RMX refeed machines.

Cutting Chambers for GF Series Film Grinders

In the cutting chambers, standard carbide-coated knives are employed, increasing the time between sharpening. The rotor knives approach the stationary bed knife, or knives, at a steep angle to ensure a clean scissors-cut. This technique is used for maximum bulk-density and flow of ground scrap. The open rotor design improves airflow for cooling , permitting the highest possible throughput.

RMX Series Refeed Machines

The unique, double-compartment RMX Series Refeed Machine operates with a variable-speed auger/bridge-breaker assembly to compact and meter ground scrap from the inner hopper to the throat of the production extruder. The outer compartment contains virgin material which is gravity-fed to the throat. The virgin material completely surrounds the ground scrap as it enters the extruder. The extruder screw receives a consistent column of compacted ground scrap surrounded by virgin material. This method provides consistent operation without extruder surging or starvation. With the standard extruder follower circuit, refeed machine will increase or decrease the scrap rate in proportion to the extruder speed. This holds scrap percentage constant without additional operator attention.

To learn more about our ASR equipment, please visit our website!

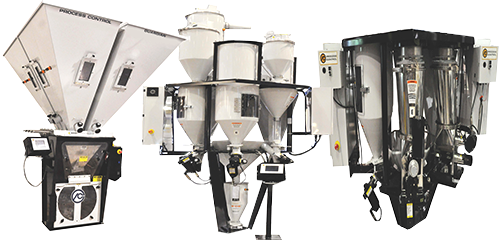

Process Control is ready to ship out a special group of Guardian Series 2 gravimetric batch blenders with regrind feeders and touch screen controls. In total, there are eleven 5kgs equipped with regrind, one standard 5kg, and two 25kg Guardian Series 2 blenders. All have the special touch screen control enclosure engineered for extreme ambient conditions.

You can read more about these special blenders through these production updates!

Blender Touch Screen Control Enclosure Engineered for Extreme Ambient Conditions

Special 5kg G2 Blenders Going Through Production

Line of blenders

View of regrind hoppers

Touch screen enclosure

There is still time to enter our Social Media Giveaway which will end today at 4pm EST!

Process Control has recently shipped a 9 Element Continuous Gravimetric Blending System including 4 Regrind Hopper Feeders (2 equipped with bridge breakers), 3 Powder Feeders and 2 Pellet Feeder Elements. The system uses state of the art, non-proprietary Touch Screen Controls, Brushless Motors and Drives. Rounding out this unique blending solution is the PCC Material Handling System which includes a Vacuum Pump, Dust Collector, Standard Powder Receivers for Dusty Regrind, and Special Powder Receiver with 70 Degree Cone and 5” Flapper Discharge.

A 5kg Guardian Series 2 Batch Blender with 8 material hoppers is ready to be shipped out from our headquarters in Atlanta, GA.

The blender also features restricted cartridge gates for ingredients below 1%. Restricted cartridge gates provide increased accuracy for component percentages below 1% by reducing the gate discharge area. As the gate retracts the amount of material released into the weigh hopper is limited by this reduced area which provides more precise control and results in a better blend and cost reduction by eliminating excessive amounts of expensive additives.

Click image to watch a video comparison of a restrictor plate vs. a normal v-gate

Process Control has a 25kg Guardian Series 2 Batch Blender going through production right now with special customized features. The 6 element blender features innovative software to allow real-time edge trim processing with automatic regrind rate adjustment utilizing multiple material hopper proximity sensors. The material hoppers are equipped with drains and quick disconnect couplings and access doors with safety interlocks. The receivers feature oversized 12″ pull-out pellet screens for ease of maintenance and magnetic open/close switches with LED.

Customized material hopper

Process Control currently has 11 special 5kg Guardian Series 2 Batch Blenders going through production for a company in the Midwest, to be shipped late next month. In addition to standard supply hoppers, these blenders have been fitted with regrind feeders equipped with horizontal cross-auger and AC drive for difficult to feed regrind material. The blenders will also have special touch screen control panels with a 55°C rating, meaning that the panels will be contained in an air conditioned enclosure in order to operate in extreme conditions. Here are some pictures of the blenders in progress. We will have an update with the special control panels in the coming weeks.

Front view of blenders

Back view of blenders