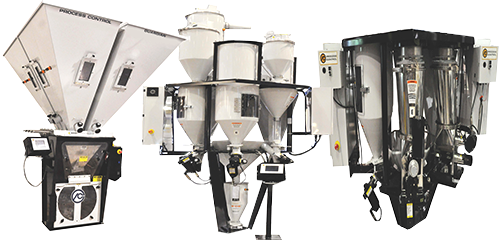

Product Spotlight: X Series 2 Continuous Blender

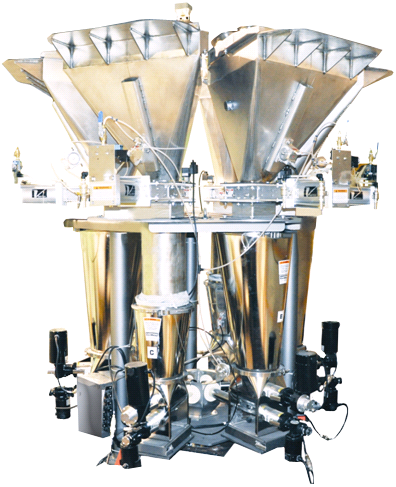

Leave a CommentThis week’s entry would like to spotlight the X Series 2 Continuous Blender. The X Series 2 is designed to produce precise, homogeneous blends by weight and offers unsurpassed blend accuracy and blend homogeneity in a wide range of configurations to meet the needs of any application. For extruder throat-mounted applications, the X Series 2 blender comes equipped with an integral downcomer to preserve the blended material all the way to the extruder without demixing. For mezzanine or off-line mounting, the blender does not include the downcomer and is designed to work with a number of different options for storing the blended material prior to it’s use.

Mechanical Features

- Individual weighed ingredient hoppers with easy-to-use drains

- Interchangable metering units with quick disconnect

- Brushless DC gear motors with closed-loop control for precise ingredient measuring

- Integral loading platform for mounting vacuum receivers

- Designed for easy clean-out and quick change over

- Color touch screen operator interface with new “off-the-shelf” control

Control Features

- Blender monitors weight loss of each ingredient hopper for precise control of blend ratios.

- Weighing system resolution is 1:1,000,000 for maximum accuracy.

- Color touchscreen display for easy viewing of inventory and performance data.

- Storage for 400 blend recipes in battery-backed memory.

- Multiple alarm levels with visual display and contact closures.

Options

- Gravimetric Extrusion Control

- Steep-wall hoppers for regrind and other sluggish materials.

- Powder Feeder metering elements

- High temperature design

Be sure to check out our videos related to the use and care of the X Series 2 Continuous Blender, such as the Material Cleanout Procedure featured on this blog. Also be sure to check in with your Process Control Sales Representative for the latest upgrades for your PCC X Series 2 Continuous Blender!

For more information on the X Series 2, click here to visit our website, check out the literature, or contact us directly at sales@process-control.com.