Product Spotlight: XU Series 2 Continuous Gravimetric Powder Blender

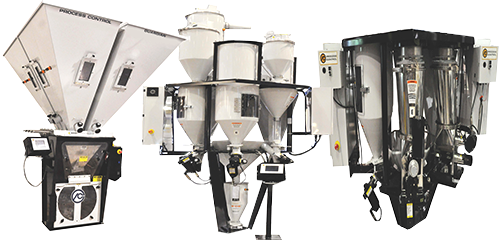

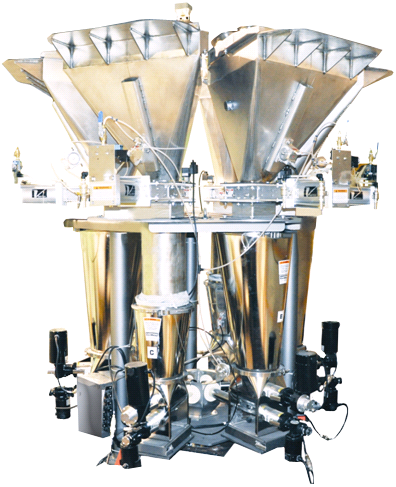

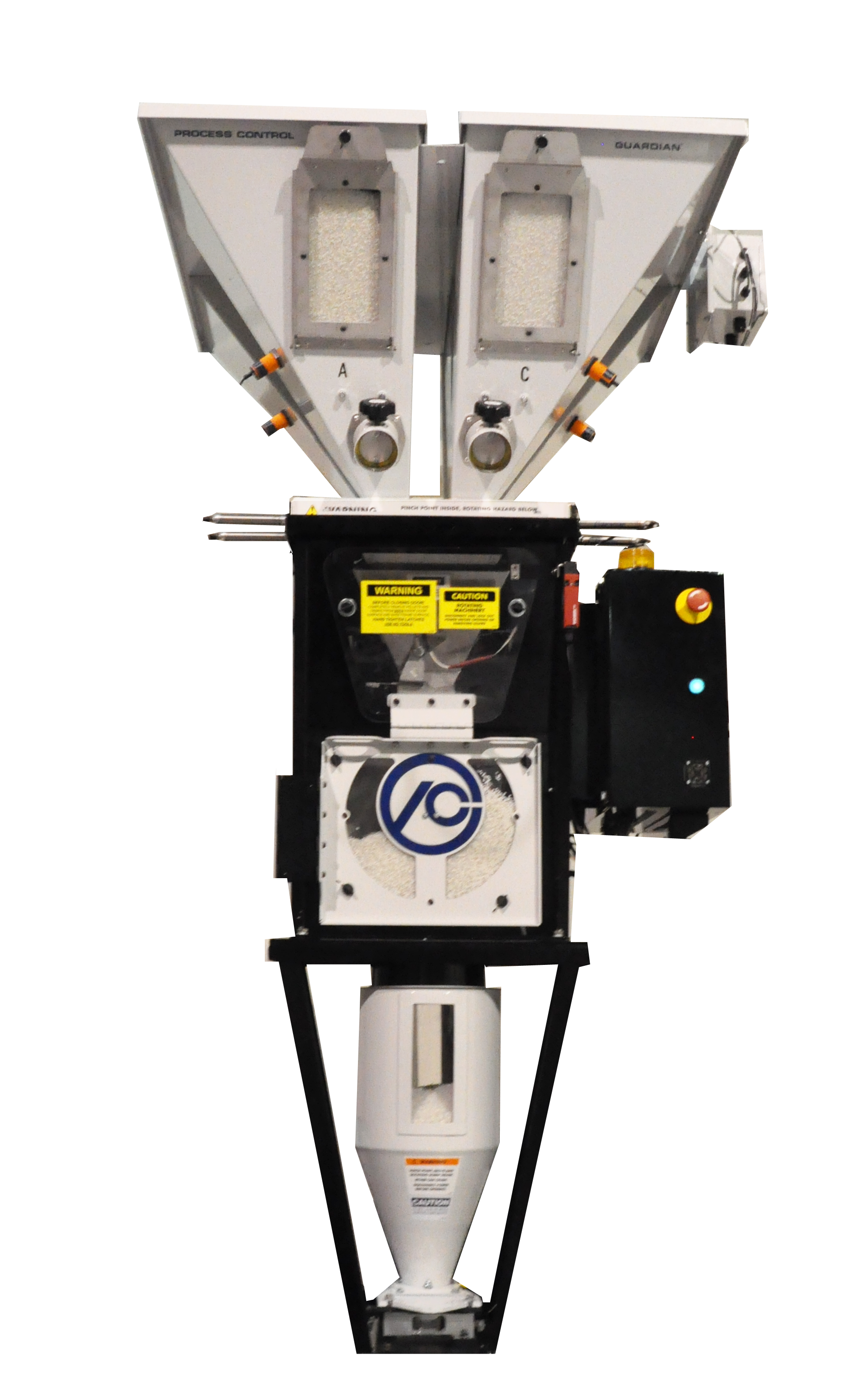

Leave a CommentToday’s blog entry will feature Process Control’s X2U Series Continuous Gravimetric Powder Blender. The X2U offers unsurpassed blend accuracy and blend homogeneity in a wide range of configurations to meet the needs of any application incorporating the PF Series powder feeders. It allows gravimetric blending of non-free-flowing powder materials with free-flowing powder and pellet materials at unprecedented metering and mixing accuracy.

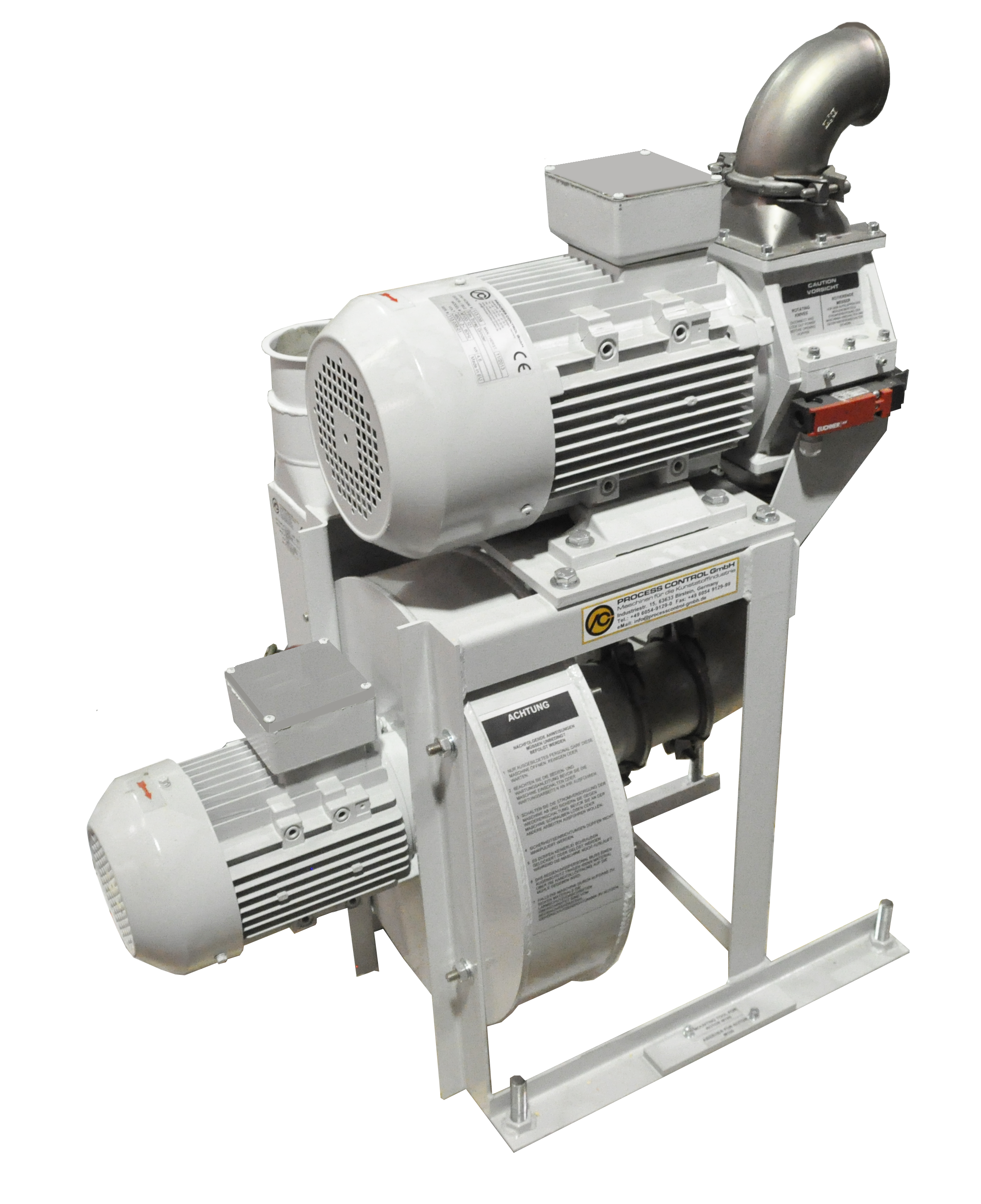

The powder feeders allow rates as low as 0.2PPH and as high as 3,000PPH. Metering augers are available in full pitch or 1/2 pitch configurations with helix diameters from 1/4 inch to 2-1/4 inches.

Incorporated into the electro-polished stainless steel design is a patented round-to-trough feeding area which provides more consistent mass flow for better metering accuracy. The feeder is designed with a steep wall, removable hopper which features a dust-tight band clamp for easy mounting of hopper extensions and quick disassembly for clean out. The bottom trough design is optimized to provide maximum material exposure to the auger.

For more information on the X2U, please visit our website or download the spec sheet. Be sure to also check out Process Control’s PF series powder feeders.