Category Archive: Gravimetric Blenders

New magnet option for Guardian 3 Batch Blenders

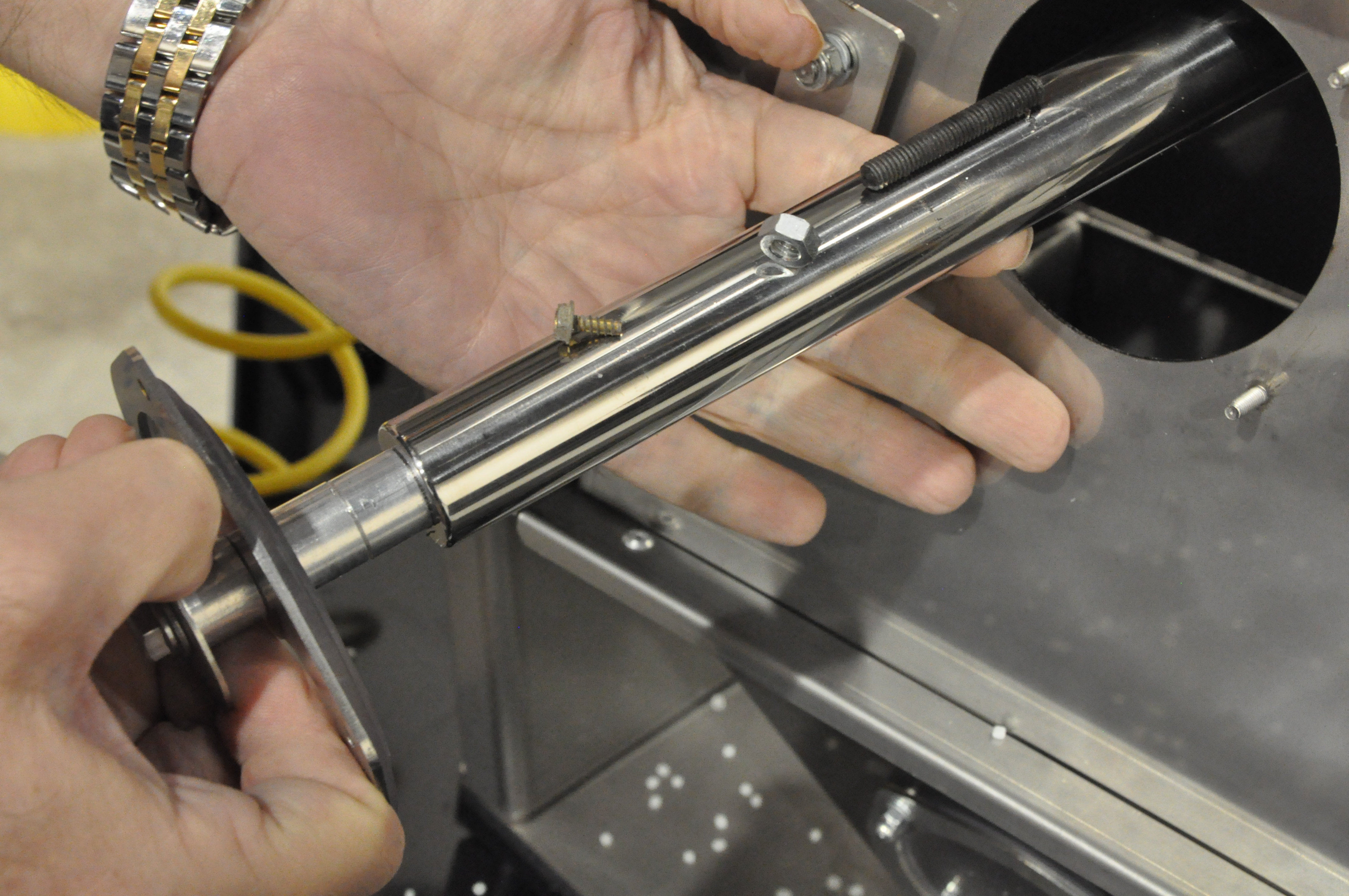

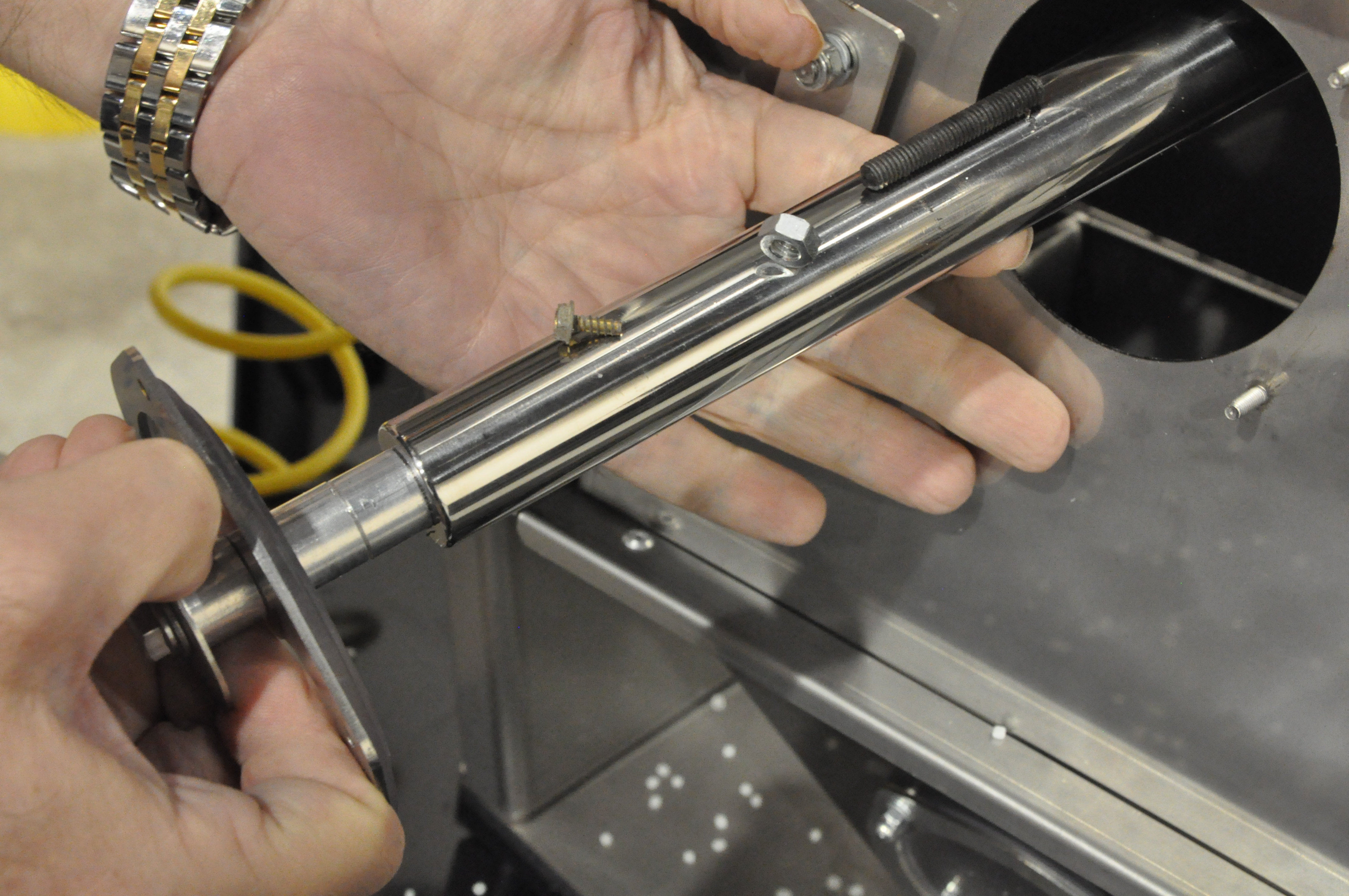

One of the latest features added to the auxiliary section of the extended base of the new Guardian 3 gravimetric batch blender is an option high powered magnet. With a single magnet positioned directly beneath the mixer discharge gate, any ferrous contamination will be caught before going to the process. This simple and low cost option eliminates the need for a separate magnet drawer, typically mounted between the blender and extruder or molding machine.

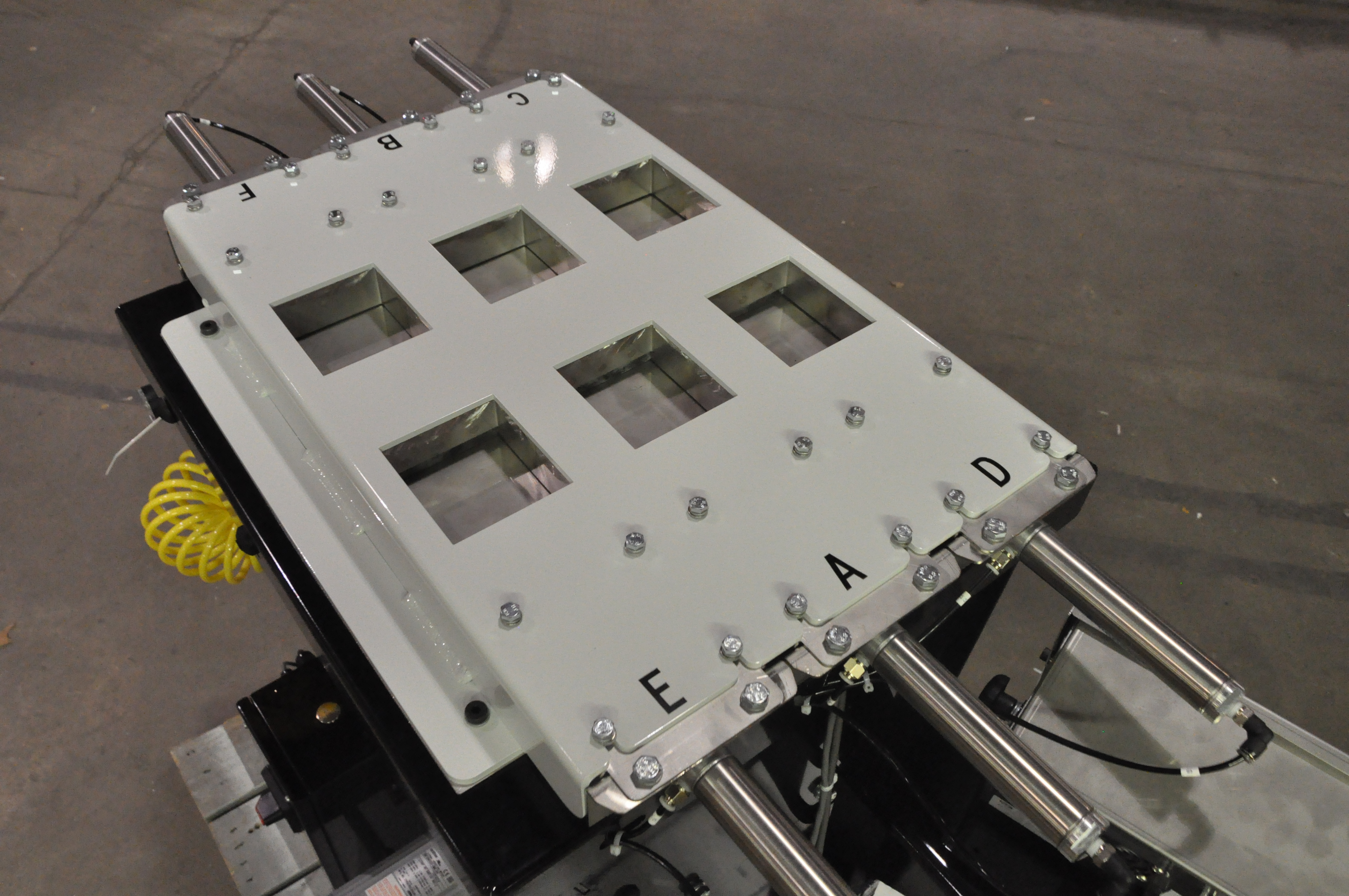

Guardian 3 base with magnet installed

Other options for the extended base include a small surge bin as shown, a funnel with hose stub for mezzanine mounting, a material pickup box for floor mounting and a weigh hopper for gravimetric extrusion control.

Guardian Series 3 Features:

- All-in-one removable metering unit and material hopper

- Improved material hopper for clean-out convenience

- Cartridge style metering gates

- Integral surge hopper option

- Stationary loading platform

- Quick-Release Polycarbonate Mixer Access Doors

- All Stainless Steel Construction

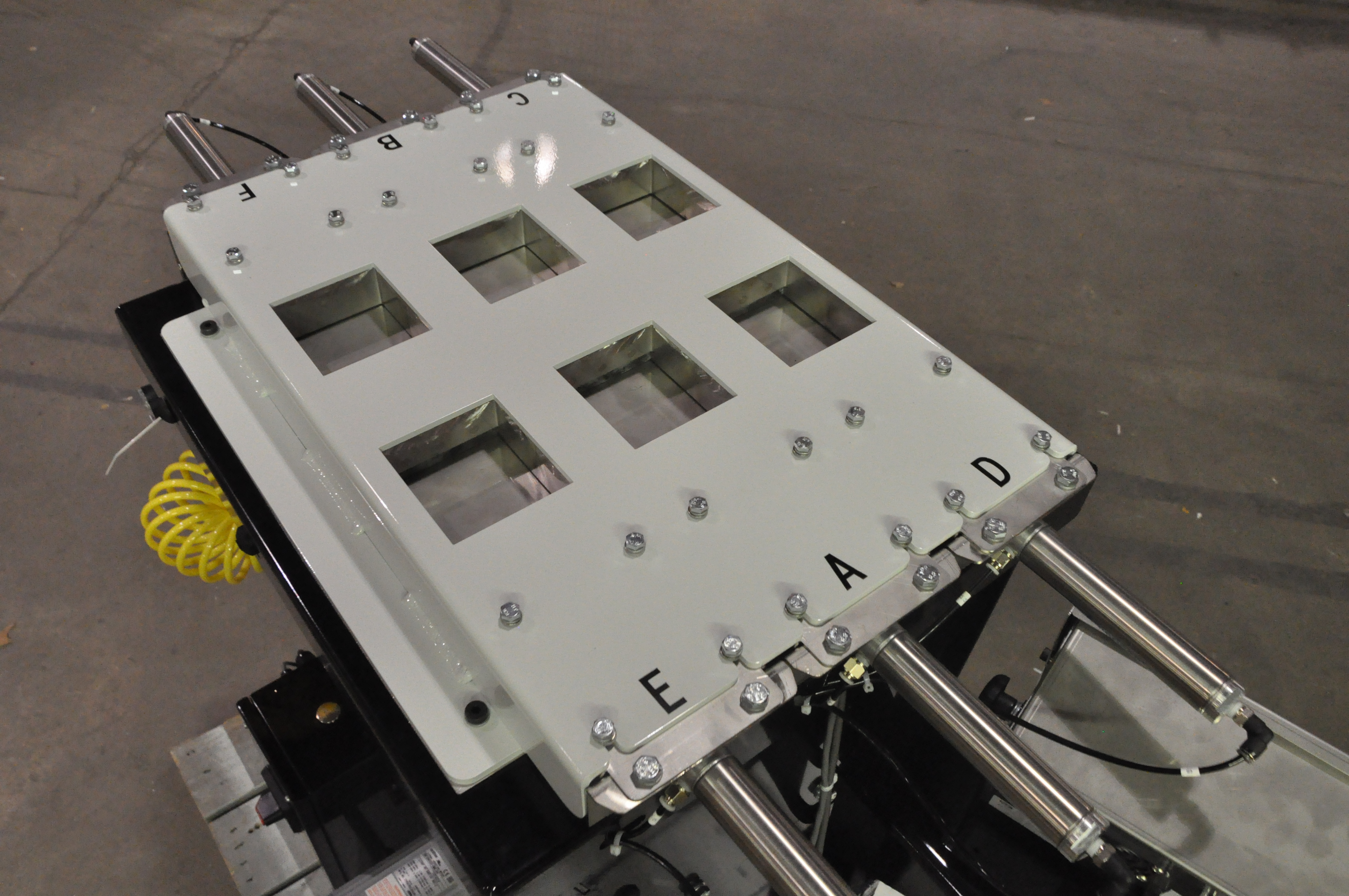

For Guardian 2 batch blending applications with severe height restrictions, as typically seen when the blender is mounted directly to the processing machine, PCC offers a design without the material hoppers. The top of the blender frame, with metering gates, allows for a custom adaption plate to provide connection to the material supply hoppers and loading equipment, typically mounted above on a mezzanine.

This hopperless design is currently available on our 2.5, 5 and 12 kg G2 blender models. This design feature helps outline PCC’s commitment to provide our customers custom engineered solutions to meet specific needs.

This week we are having a promotion for new subscribers to our blog, facebook, twitter, or linkedin! All new subscribers between now and Thursday afternoon will receive a FREE PCC Jotter package.

Happy 2013 from Process Control Corporation!

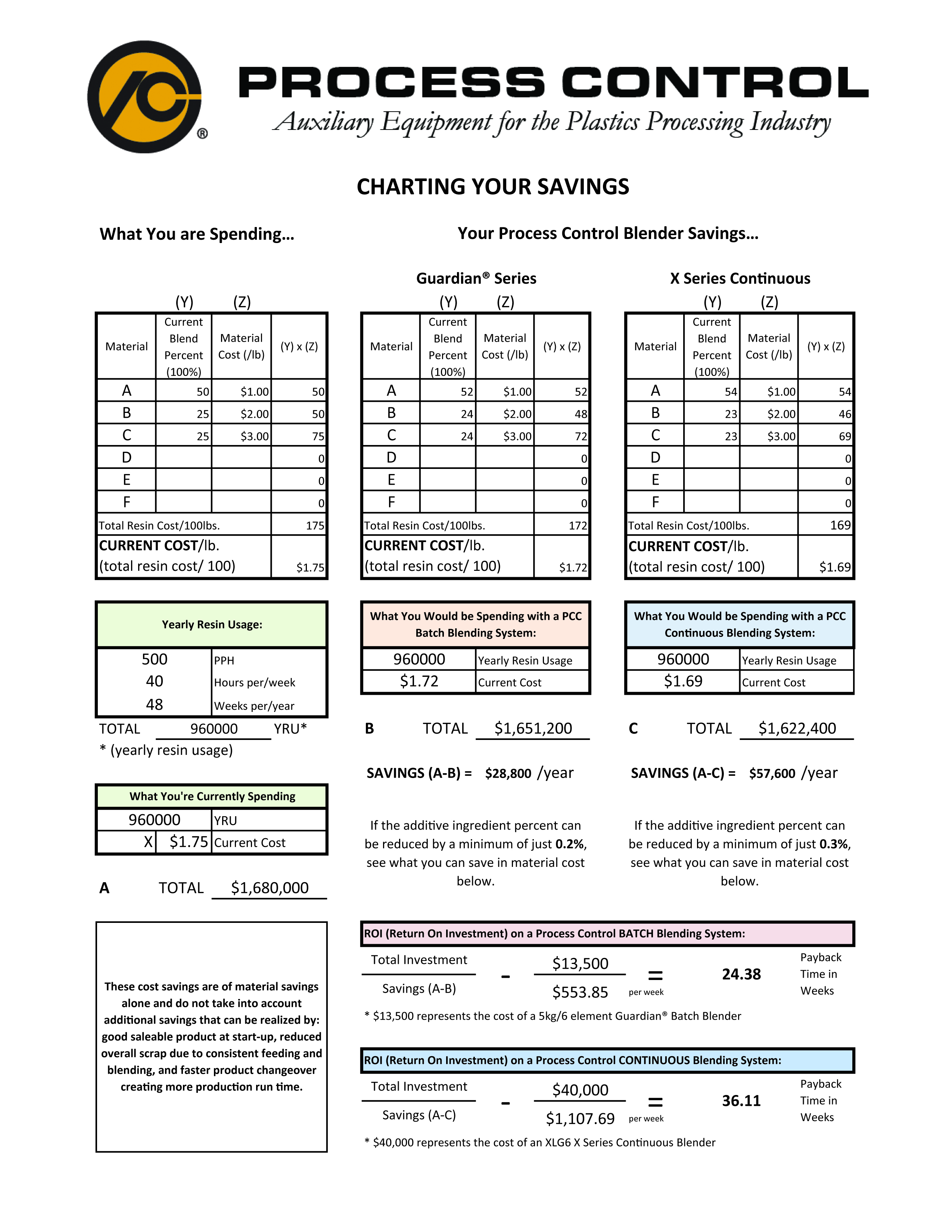

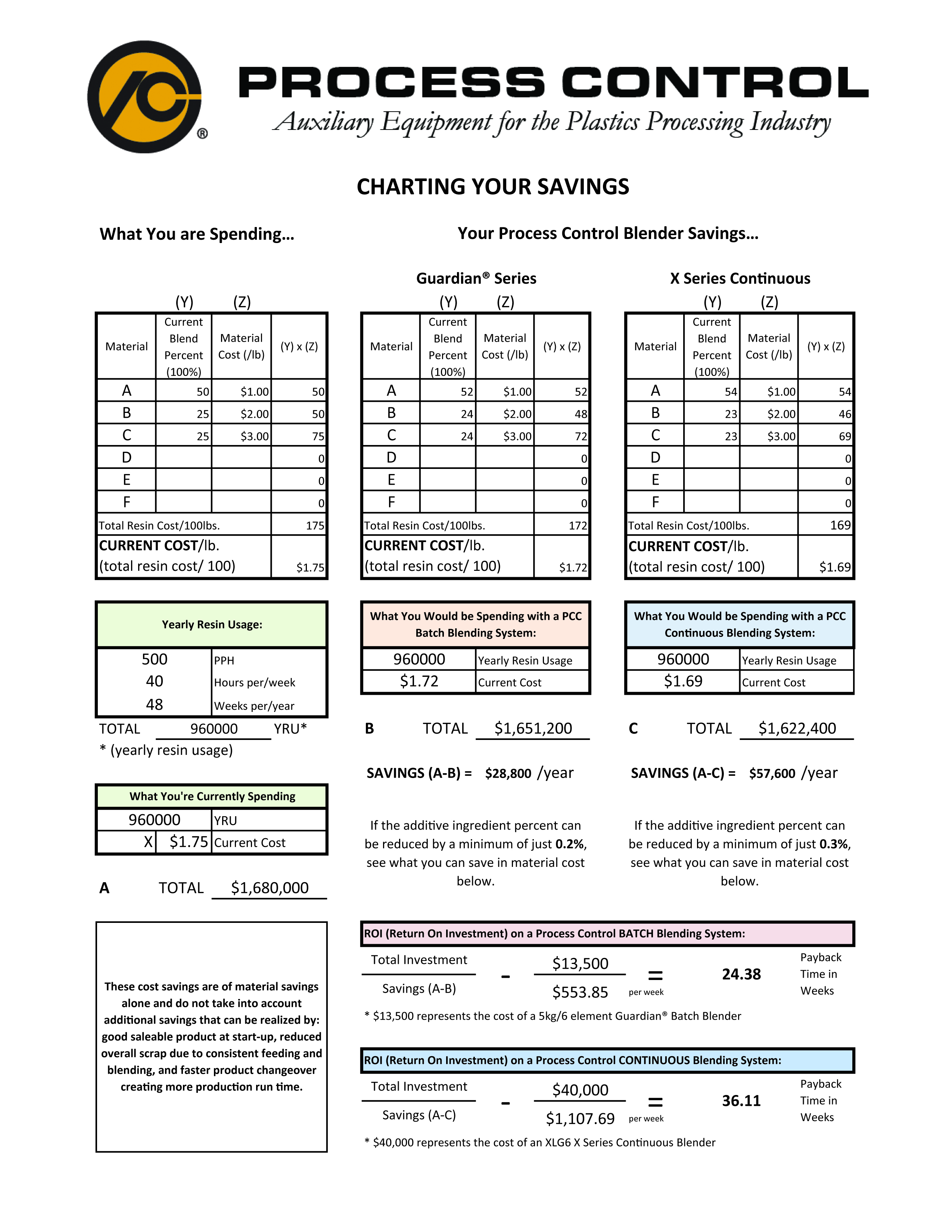

To kick off the new year, we would like to invite you to take a look at how much you can save by investing in a PCC Blending System. We have developed two blending systems to put you on the most efficient path to feed and mix accuracy while still producing a high quality end product. By precisely metering and blending resins and additives, we have created the most accurate, cost effective blending systems for processors.

The following spreadsheet documents the potential savings you could gain by operating either a PCC Batch Blender or PCC Continuous Blender. If you would like a more personalized look at what your company could save, you can find a PCC sales representative in your area, or contact us directly at sales@process-control.com.

Process Control GmbH (PCC’s German subsidiary) currently has a special six element continuous blender going through production. Three hoppers on the blender are for powder material and the other three are fed with regrind. The powder feeders are installed on a slide base that can be easily removed for cleaning purposes. There is also a separate base for feeding powders to a side feeder. The small base for the single powder feeder has a turnable upper plate so that the feeder can be set to both of the side feeders on the extruder.

Check out this video of a Guardian Series 2 Batch Blender dispensing material from the metering gates. One gate has the standard v-gate design (right) while the other (left) has a restrictor plate installed. The restrictor plate gives processors the ability to finely control low rate ingredients for even greater batch accuracy.

[youtube=http://youtu.be/XvaZ3IZxKeU]

PCC has recently shipped two 2.5kg Guardian Series 2 batch blenders, each with a powder feeder in place of one of the standard material hoppers with high and low proximity sensors. The stainless steel feeder will mix powder material with regrind and pellets.

In November’s issue of Plastics Technology, has written a featured article about the least understood aspects of blending. The article discusses the differences between batch and continuous blenders, how blend accuracy is calculated and controlled, which blender type is more accurate, how much accuracy is really required, and how payback is calculated.

Click here to read the full article.

PCC has made a new video of the mixing process of our Guardian Series 2 batch blenders. The demo shows 95% virgin mixed with 5% color as being dispensed from the weigh hopper above. Less than a 15 second mix cycle is all that is required to provide a homogenous blend for the process.

[youtube=http://youtu.be/ntRUbrgDQe8]

Process Control is pleased to announce that the first 1kg Guardian Series 2 Gravimetric Batch Blender has been shipped.

The product of cutting edge design and engineering, this all stainless steel blender features incredibly easy clean-out and material changes, superior accuracy, and is available with up to 4 elements and up to 350 PPH.

For more information on this blender, please visit our website or contact us at sales@process-control.com

PCC recently supplied a Blending System for Mono-Extrusion Control. This impressive structure, which includes a Model XLE 6-Component Continuous Gravimetric Blender, vacuum receivers, surge hopper, weighed down comer and custom magnet drawer, is extruder mounted. The Blender, equipped with brushless motors and drives, uses a combination of high rate pellet hoppers, low rate tube hoppers and a regrind hopper for a throughput of up to 2,000 PPH. A nice twist allows the 10 cubic foot surge hopper to be filled with blended material when the extruder is down, by pneumatically conveying from an aspirated stub on the side of the magnet drawer.

Blending System for Mono-Extrusion