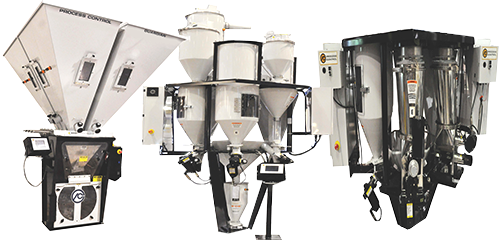

PCC recently supplied a Blending System for Mono-Extrusion Control. This impressive structure, which includes a Model XLE 6-Component Continuous Gravimetric Blender, vacuum receivers, surge hopper, weighed down comer and custom magnet drawer, is extruder mounted. The Blender, equipped with brushless motors and drives, uses a combination of high rate pellet hoppers, low rate tube hoppers and a regrind hopper for a throughput of up to 2,000 PPH. A nice twist allows the 10 cubic foot surge hopper to be filled with blended material when the extruder is down, by pneumatically conveying from an aspirated stub on the side of the magnet drawer.