Completing the ASR Part Three: The GF Series Film Grinder

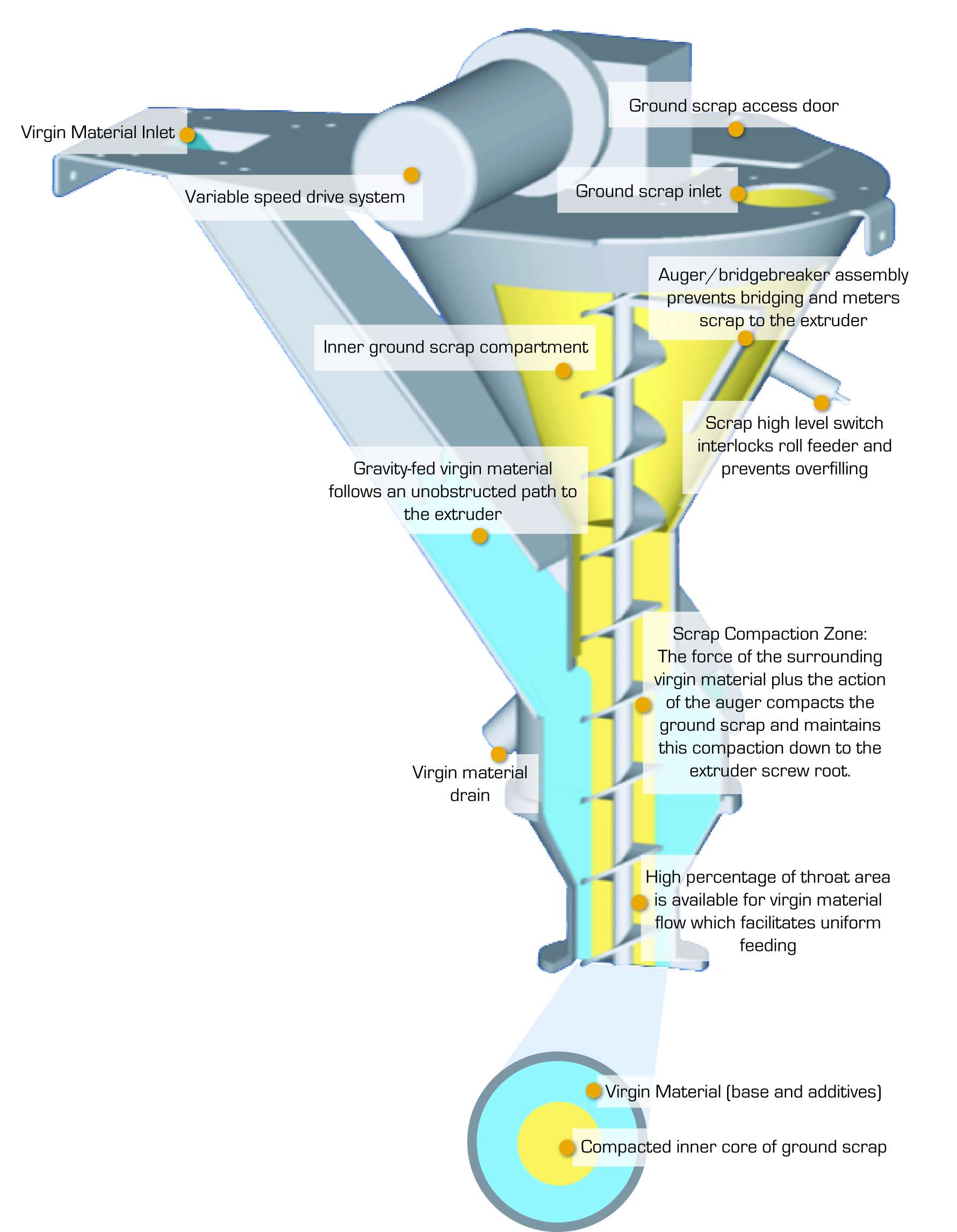

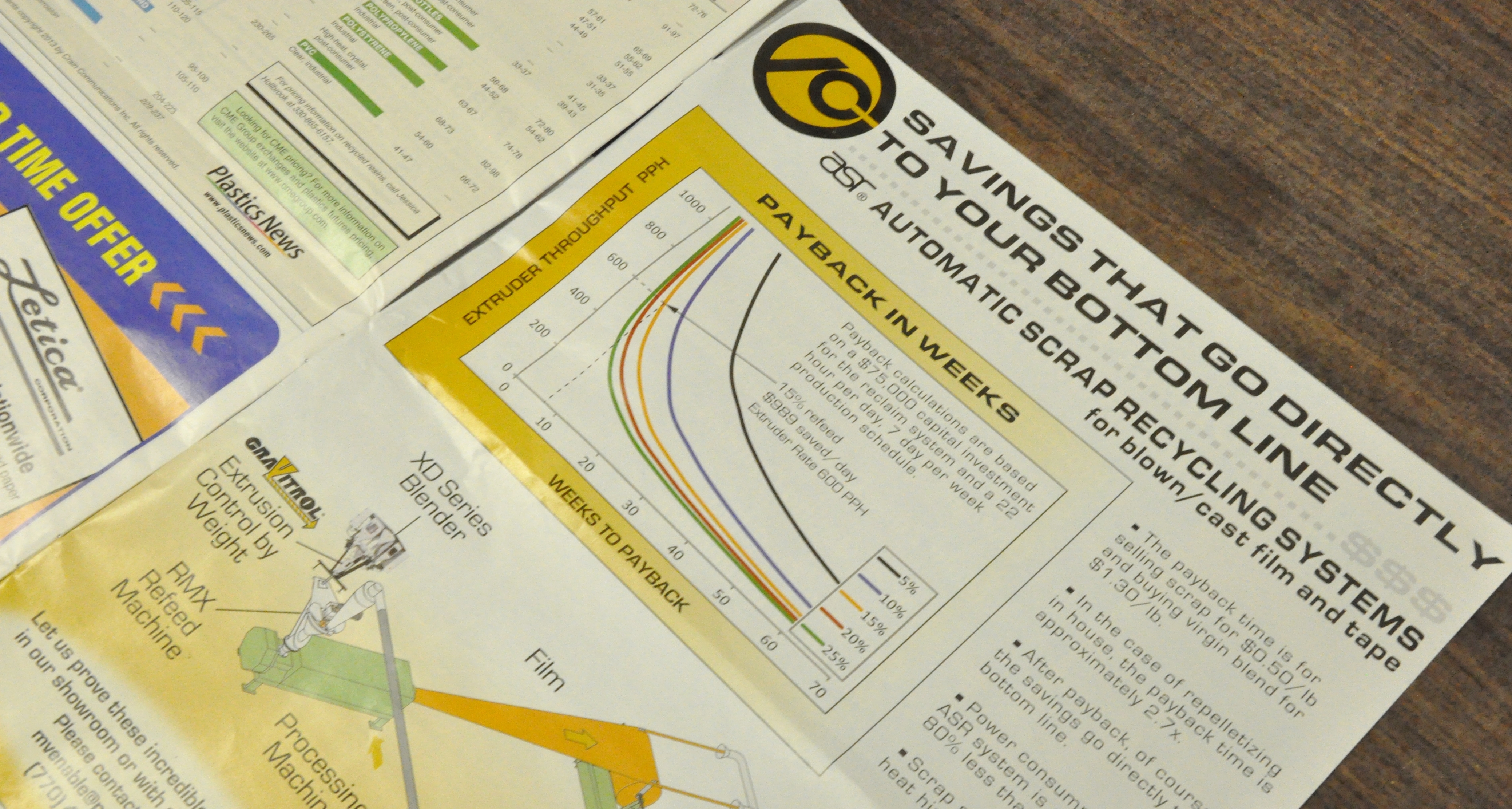

Leave a CommentThe recovery of scrap generated during the production of blown film, cast film, tape and extrusion coating processes is a key element in reducing manufacturing costs. The Automatic Scrap Recycling system – or ASR®, for short – can recycle trim scrap and off-spec roll scrap in-line and turn your scrap back into profit without the expense of repelletizing.

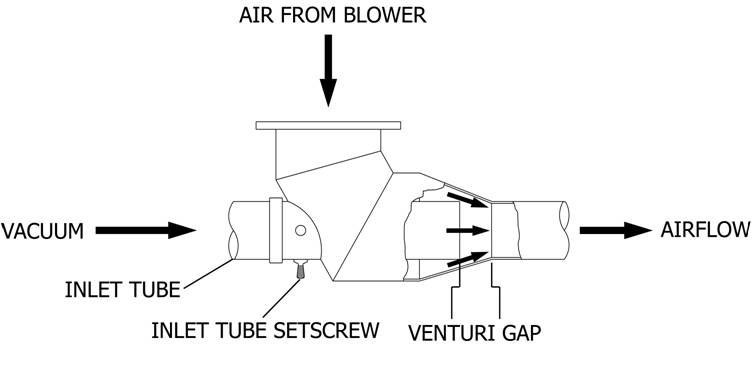

A complete ASR system consists of several components, and for the next three weeks Process Control is pleased to detail this patented Automatic Scrap Recycling system. The three components covered will include the following: The RMX Series Refeed Machine, the IN Series Trim Removal Inducer, and the GF Series Film Scrap Grinder.

This week, PCC would like to highlight the features of our GF Series Film Grinder for automatic scrap recycling applications.

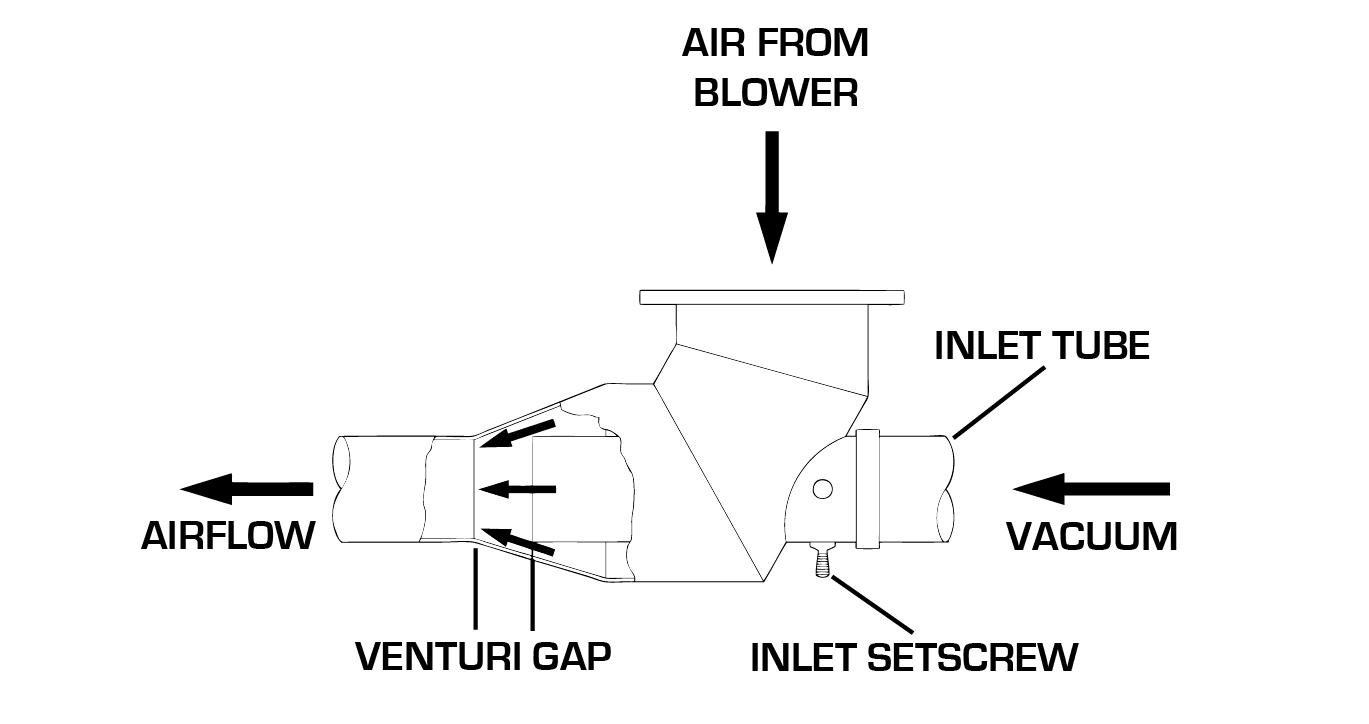

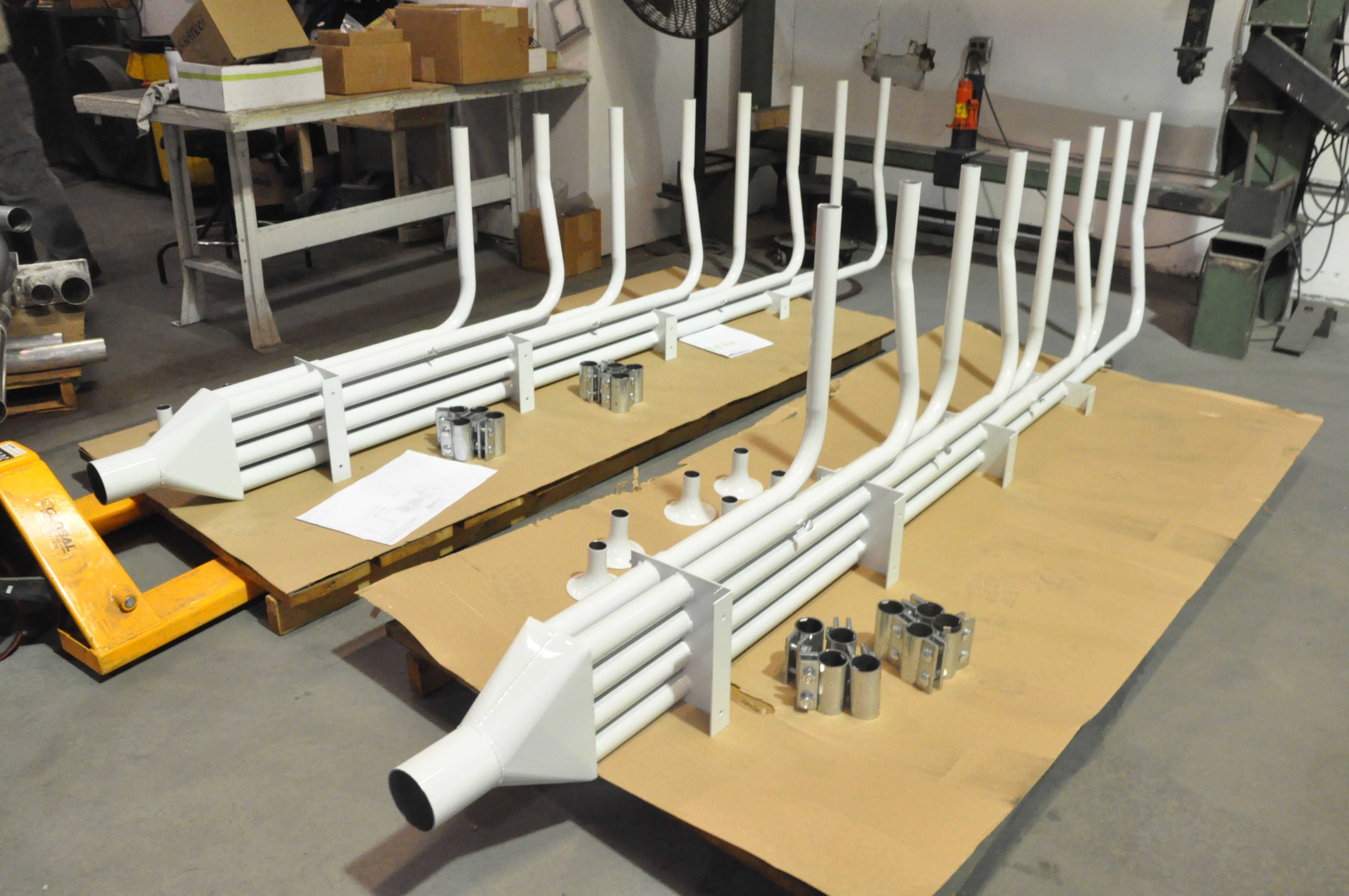

The GF Series grinders from PCC are used as part of an ASR Automatic Scrap Recycling system for in-line recycling of production film scrap. GF grinders are designed to provide efficient, uniform grinding o film scrap. There are four cutting chamber sizes available along with different horsepower motors to accurately match the grinder to the scrap rate. Grinders are available in configurations that accept edge and bleed trims, roll scrap, and loose scrap.

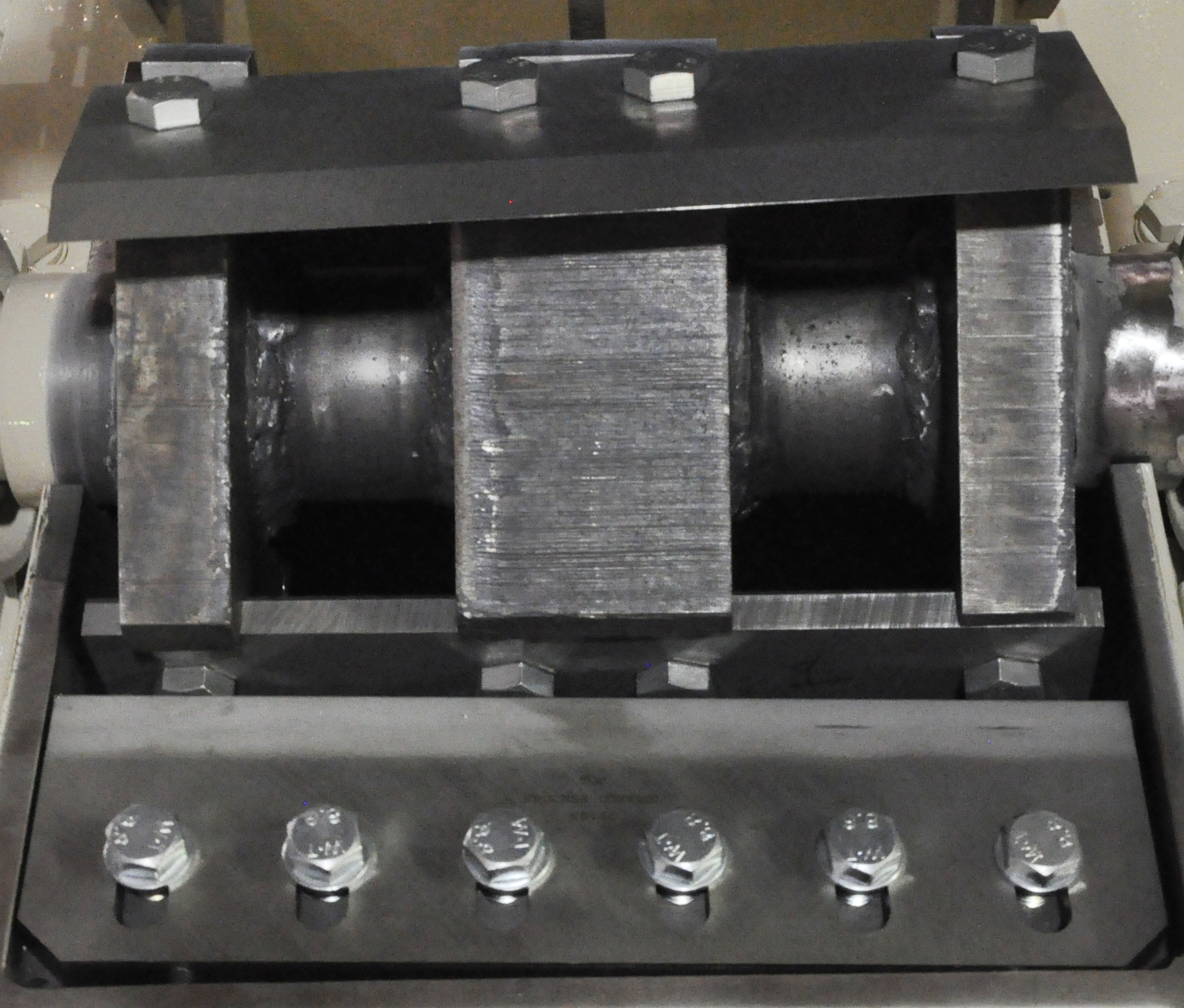

Standard carbide-coated knives are employed in the system, increasing the time between sharpening. The rotor knives approach the stationary bed knife, or knives, at a steep angle to ensure a clean scissor cut. This technique is used for maximum bulk-density and flow of ground scrap. The open rotor design improves airflow for cooling, permitting the highest possible throughput.

Click here for more information on the GF Series Film Grinder.

For more information on the ASR® Automatic Scrap Recycling System and Process Control’s other products and upgrades , please visit our website or contact us directly at sales@process-control.com.